In an era where safety on the roads is of utmost importance, Ontario is leading the charge by implementing groundbreaking X-ray technology for commercial vehicle inspections. This state-of-the-art advancement aims to streamline the inspection process, significantly enhancing both efficiency and effectiveness in monitoring commercial transport. With X-ray scanners deployed across the province, the Ontario Transportation Ministry is set to revolutionize how cargo inspections are conducted, ensuring compliance with regulations while prioritizing safety.

As drivers temporarily exit their vehicles for these non-intrusive scans, Ontario is not just adopting new technology but is also pledging a commitment to safer communities and roadways. The result is a proactive approach to vehicle inspections that promises to bolster public safety and instill greater confidence in the transportation sector.

Join us as we delve deeper into how this innovative tool will transform the commercial vehicle inspection landscape in Ontario and its potential impact on the future of transportation safety.

Benefits of X-ray Inspection Technology

Using X-ray inspection technology for commercial vehicles offers many benefits that boost efficiency, safety, and compliance with regulations.

Improved Efficiency

- Automates defect detection to save time

- Real-time imaging for quick problem finding

- Increases number of vehicles inspected per hour

X-ray systems automate the detection of defects, which saves time compared to manual inspections. For example, digital radiography allows inspectors to capture images in real time. This lets them quickly find problems, which speeds up the entire inspection process and increases the number of vehicles inspected.

Enhanced Safety

- Detects internal structural defects often missed

- Ensures vehicles meet safety standards

- Expert analysis enhances safety with thorough inspections

Safety is essential in commercial transport, and X-ray technology improves it. By finding internal structural defects that other methods might overlook, X-ray inspections help ensure vehicles meet the necessary safety standards before they travel. Experts say that examining complicated components closely helps detect even tiny faults, which significantly boosts vehicle safety.

Regulatory Compliance

- Detailed scan data reduces regulatory violations

- Builds trust with regulators and the public

- Supports accountability through documented inspections

With strict rules in place for commercial transport, X-ray technology helps companies stay compliant. The detailed data from X-ray scans not only reduces violations but also builds a strong case for accountability. This trust with regulators and the public shows that inspections are taken seriously. Geoff Wood, from the Ontario Trucking Association, said, "With this latest announcement, we are entering another phase and use of this critical MTO infrastructure to greatly expand its capabilities. We need this technology adopted by all provinces across Canada."

Conclusion

In summary, adopting X-ray inspection technology in vehicle inspections is crucial for improving efficiency, safety standards, and regulatory compliance. This technology changes how inspections are done and strengthens the commitment to public safety in transportation.

Adoption of X-ray Inspection Technologies in the Transportation Sector

The adoption of X-ray inspection technologies in the transportation sector is on the rise, highlighting their effectiveness and user satisfaction. Recent data demonstrates the significance of these advancements:

- User Adoption Rates: X-ray vehicle scanners comprised over 40% of the global vehicle scanner market by 2024. Nearly 900 X-ray scanners were reported to be installed at key border checkpoints worldwide by mid-2023, indicating robust global adoption.

- Effectiveness: Companies implementing X-ray systems have significantly improved operational efficiency. For instance, in Southeast Asia, inspection times were reduced from 45 minutes to under 20 minutes due to the introduction of these technologies. In the automotive industry, over 35% of manufacturers report using X-ray inspection tools for enhanced defect detection, achieving higher accuracy compared to traditional inspections.

- User Satisfaction: The ability of X-ray systems to identify various materials with minimal false alarms has led to greater user satisfaction. This versatility in application ensures enhanced security and operational efficiency, thus fostering trust among transportation agencies and service providers.

- Alignment with Current Technologies: Integration with AI and digital advancements has positioned X-ray inspection systems as essential tools within modern transportation frameworks. More than 60% of manufacturers are now emphasizing AI-enabled tools to enhance detection accuracy, thus signifying a shift towards smarter, more advanced transportation inspection methodologies. Furthermore, the rise of electric vehicles and advanced driver-assistance systems necessitates precise inspections, further driving the adoption of X-ray technologies.

As Ontario implements X-ray inspection technology for commercial vehicle inspections, these trends reflect a broader movement towards enhanced safety and efficiency in transportation. By leveraging advanced X-ray systems, Ontario is not just embracing innovative technologies but is also committing to a safer future for road transport.

| Factor | Traditional Inspection Methods | X-ray Inspection Technology |

|---|---|---|

| Time Taken | Longer, often exceeding 30 minutes | Typically under 20 minutes |

| Safety Outcomes | Limited detection of internal defects | High detection rate of internal defects |

| Regulatory Compliance | Subject to human error, inconsistent | Enhanced accuracy, reliable data for compliance |

Addressing Driver Concerns Regarding X-ray Inspection Technology

As Ontario progresses with the introduction of X-ray inspection technology, drivers may have several concerns related to this modernization of commercial vehicle inspections. It is vital to address these apprehensions to foster understanding and acceptance of the new procedure.

Exiting Vehicles for Inspection

One of the primary concerns for drivers is the requirement to exit their vehicles during the scanning process. While this may be seen as inconvenient, it is essential to understand that this step is crucial for safety and efficiency. Drivers can expect a streamlined process that minimizes overall wait times while ensuring thorough inspections. With X-ray technology, the actual scanning process is rapid and efficient, typically taking less time than traditional methods, contributing to quicker returns to the road.

Impact on Routine and Scheduling

Drivers often have tight schedules, and any delay can have a ripple effect on their deliveries. The implementation of X-ray technology is designed to enhance, not hinder, operational efficiency. The inspections are expected to be completed swiftly, allowing drivers to maintain their schedules more effectively than with previous inspection methods.

Privacy and Safety Concerns

Another significant concern revolves around the privacy of drivers and the safety of their cargo. Drivers may worry whether the X-ray technology could expose sensitive information or personal belongings inside the vehicle. It is important to communicate that X-ray inspections are non-intrusive and focused solely on the structural integrity and safety of the vehicle without breaching personal privacy. These scans are conducted in compliance with safety regulations, ensuring that the process protects both the drivers’ privacy and their cargo.

Overall Experience During Inspections

The implementation of this technology represents a shift towards more advanced and effective inspection processes. As drivers adapt to these changes, the experience is expected to become more efficient and less stressful. The Ontario Transportation Ministry is committed to ensuring that the transition to X-ray technology is accompanied by clear communication and support, helping drivers feel secure and informed throughout the inspection process.

In conclusion, while the transition to X-ray inspection technology introduces some changes to the inspection experience for drivers, the overall benefits of improved efficiency, safety, and compliance are significant. Engaging with drivers to clarify concerns will be vital in ensuring a smooth implementation and fostering a positive perception of this innovative advancement in commercial vehicle inspections.

Conclusion

In conclusion, the deployment of X-ray inspection technology marks a pivotal advancement in Ontario’s approach to commercial vehicle safety, reinforcing the benefits of efficiency, safety, and compliance. This innovative technology has proven to enhance inspection efficiency, ensure high safety standards, and strengthen regulatory adherence in the transportation sector. By allowing for timely and thorough inspections, X-ray technology ensures early detection of potential issues, confirming that all vehicles on the road meet strict safety criteria.

The proactive commitment of the Ontario Transportation Ministry to integrate this cutting-edge technology underscores an unwavering focus on public safety, while actively engaging with drivers to address their concerns about the scanning process reflects a dedication to transparency and trust. As noted in recent findings, X-ray technology not only significantly reduces inspection times—from 45 minutes to under 20 minutes—but also enhances the detection capabilities for hidden internal defects, crucial for maintaining vehicle safety.

In summary, the benefits of X-ray inspection technology are clear: it streamlines operations, fosters trust with stakeholders, and aims to create a safer environment for all road users. The projected growth of this technology, which is expected to reach a market value of US$3.06 billion by 2033, signifies its integral role in the evolving landscape of transportation safety. With advancements like these, the future of transportation safety looks brighter, promising enhanced compliance and an enduring commitment to community well-being.

Future Implications of X-ray Inspection Technology for the Trucking Industry

The introduction of X-ray inspection technology is set to revolutionize the trucking industry in Ontario, with significant future implications on both operational efficiency and enforcement capabilities. As outlined by Ontario’s Transportation Minister, Prabmeet Sarkaria, this innovative approach is designed not only to enhance the effectiveness of cargo inspections but also to bolster public safety by improving compliance among transport operators.

Enhancements to Enforcement Capabilities

Geoff Wood, Senior Vice-President of Policy at the Ontario Trucking Association, highlighted that this technology’s deployment will vastly expand enforcement capabilities. By facilitating the identification of undocumented cargo and illegal shipments, X-ray technology represents a crucial step towards restoring trust within the industry. This advancement is particularly important in a regulatory environment where safety is paramount. Wood further stated, “Understanding the current state of the industry, this technology is a requirement if we are going to restore trust and eliminate risks to public safety.”

Additionally, the Ministry of Transportation (MTO) has been intensifying its enforcement initiatives through programs such as Operation Deterrence, which has already led to significant findings, including the impoundment of vehicles with major safety issues. The MTO’s commitment to modernizing enforcement measures through technology exemplifies a proactive approach to addressing safety concerns in commercial transportation.

Integration with Digital Initiatives

The implementation of X-ray systems is part of a broader strategy aimed at digitizing vehicle safety and emissions inspections through initiatives like the DriveON program. This program seeks to streamline inspection processes further, reduce vehicle downtime, and minimize opportunities for fraud. By integrating advanced X-ray technology into these efforts, Ontario is positioned to significantly enhance compliance rates among trucking operators, ultimately contributing to a safer transportation environment.

Collaborative Legislative Changes

In tandem with these technological advancements, the Ontario government is exploring legislative changes to grant increased authority to the Registrar of Motor Vehicles. This move aims to improve oversight of Commercial Vehicle Operator’s Registration (CVOR) certificates, making it easier to address safety and compliance issues, and providing clearer guidelines for enforcement actions.

In summary, the future implications of X-ray inspection technology for the trucking industry in Ontario are profound. With enhancements to enforcement capabilities and a commitment to safety and compliance, this initiative positions Ontario as a leader in modern transportation safety practices, paving the way for a more secure and efficient trucking industry.

FAQ on X-ray Inspection Technology

1. What is X-ray inspection technology in commercial vehicles?

X-ray inspection technology uses advanced imaging techniques to scan commercial vehicles, allowing inspectors to see inside cargo holds and detect any safety issues or illegal items without the need for invasive searches.

2. Will drivers need to exit their vehicles during the inspection?

Yes, drivers will need to exit their vehicles while the scanning is performed. However, the process is designed to be quick, ensuring minimal disruption to their schedules.

3. How long does the X-ray inspection take compared to traditional methods?

The X-ray inspection process is typically faster than traditional inspection methods, usually taking less than 20 minutes, while traditional inspections often exceed 30 minutes.

4. What kind of issues can X-ray inspections detect?

X-ray inspections can help identify structural defects, hidden cargo, and other safety compliance issues that might not be visible during a standard inspection.

5. Are there any privacy concerns for drivers?

X-ray inspections are non-intrusive and focus exclusively on vehicle safety. The process does not expose personal belongings or sensitive information about the driver or cargo.

6. How does this technology improve safety for drivers and the public?

By allowing for thorough inspections that identify potential safety issues before vehicles hit the road, X-ray inspection technology helps prevent accidents and enhances public safety through better compliance with regulations.

7. What are the overall benefits of using X-ray inspection technology?

Benefits include faster inspection times, improved detection of internal defects, enhanced compliance with safety regulations, and increased overall efficiency in the inspection process.

8. Is this technology being widely adopted in other regions?

Yes, X-ray inspection technology is gaining traction globally, with many regions implementing similar systems to enhance commercial vehicle safety and improve operational efficiencies.

Stakeholder Quotes on X-ray Inspection Technology

The Ontario Transportation Ministry’s approach to X-ray inspection technology has stirred positive feedback from key stakeholders, emphasizing the commitment to enhance road safety and the effective use of innovative techniques in commercial vehicle inspections.

Ontario Transportation Minister Prabmeet Sarkaria noted:

“We’re using new, innovative technology to make our roads safer. #MTO enforcement officers are now using X-ray scanners to make cargo inspections more effective.”

(Truck News)

Geoff Wood, senior vice-president of policy at the Ontario Trucking Association (OTA), supported the initiative and highlighted its importance:

“With this latest announcement, we are entering another phase and use of this critical MTO infrastructure by adding tools necessary for enforcement to vastly expand its capabilities, including the identification of undocumented cargo and illegal shipments…”

(Truck News)

Wayne Cooney, OTA’s secretary treasurer, expressed his support after witnessing the technology in action:

“I was impressed by MTO staff in attendance and Minister Sarkaria’s commitment to making our roads and communities safer.”

(Truck News)

These quotes underscore the shared optimism surrounding the deployment of X-ray inspection technology as a significant step towards improving the efficiency and safety of commercial vehicle inspections in Ontario.

Visual Illustrations on X-ray Inspection Technology

To enhance engagement and storytelling in our article about Ontario’s deployment of X-ray inspection technology, here are some visual representations:

X-ray Inspection Technology Overview

Illustration showing the X-ray inspection process for commercial vehicles, highlighting the scanning operations and driver interactions.

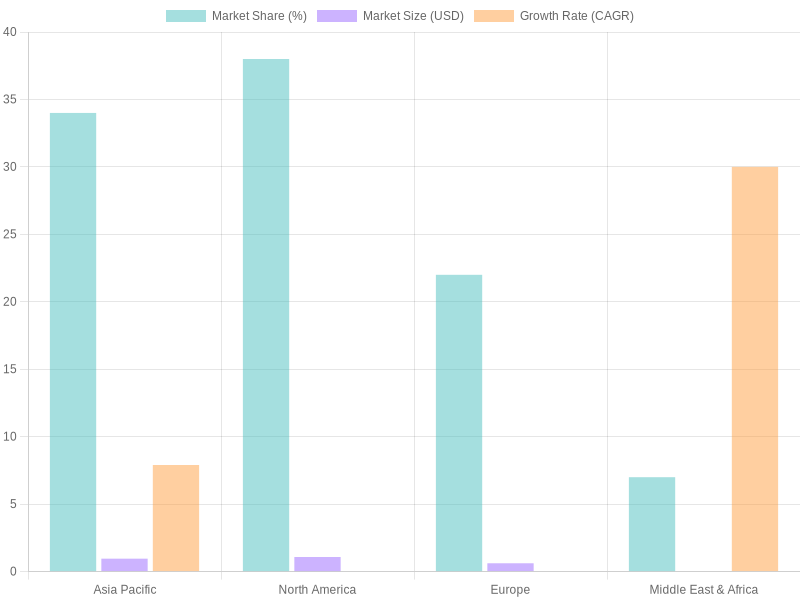

Adoption Rates of X-ray Inspection Technology

Chart illustrating the market share, market size, and growth rates of X-ray inspection technology across different regions from 2020 to 2025.

These images help visualize the transformative impact X-ray technology will have on commercial vehicle inspections, emphasizing its benefits in safety, efficiency, and regulatory compliance.

In an era where safety on the roads is of utmost importance, Ontario is leading the charge by implementing groundbreaking X-ray technology for commercial vehicle inspections. This state-of-the-art advancement aims to streamline the inspection process, significantly enhancing both efficiency and effectiveness in monitoring commercial transport. With X-ray scanners deployed across the province, the Ontario Transportation Ministry is set to revolutionize how cargo inspections are conducted, ensuring compliance with regulations while prioritizing safety. As drivers temporarily exit their vehicles for these non-intrusive scans, Ontario is not just adopting new technology but is also pledging a commitment to safer communities and roadways. The result is a proactive approach to vehicle inspections that promises to bolster public safety and instill greater confidence in the transportation sector. Join us as we delve deeper into how this innovative tool will transform the commercial vehicle inspection landscape in Ontario and its potential impact on the future of transportation safety.

Benefits of X-ray Inspection Technology

Using X-ray inspection technology for commercial vehicles offers many benefits that boost efficiency, safety, and compliance with regulations.

Improved Efficiency

- Automates defect detection to save time

- Real-time imaging for quick problem finding

- Increases number of vehicles inspected per hour

X-ray systems automate the detection of defects, which saves time compared to manual inspections. For example, digital radiography allows inspectors to capture images in real time. This lets them quickly find problems, which speeds up the entire inspection process and increases the number of vehicles inspected.

Enhanced Safety

- Detects internal structural defects often missed

- Ensures vehicles meet safety standards

- Expert analysis enhances safety with thorough inspections

Safety is essential in commercial transport, and X-ray technology improves it. By finding internal structural defects that other methods might overlook, X-ray inspections help ensure vehicles meet the necessary safety standards before they travel. Experts say that examining complicated components closely helps detect even tiny faults, significantly boosting vehicle safety and compliance.

Regulatory Compliance

- Detailed scan data reduces regulatory violations

- Builds trust with regulators and the public

- Supports accountability through documented inspections

With strict rules in place for commercial transport, X-ray technology helps companies stay compliant. The detailed data from X-ray scans not only reduces violations but also builds a strong case for accountability. This trust with regulators and the public shows that inspections are taken seriously. Geoff Wood, from the Ontario Trucking Association, said, “With this latest announcement, we are entering another phase and use of this critical MTO infrastructure to greatly expand its capabilities. We need this technology adopted by all provinces across Canada.”

Adoption of X-ray Inspection Technologies in the Transportation Sector

X-ray inspection technologies in the transportation sector are on the rise, highlighting their effectiveness and user satisfaction. Recent data demonstrates the significance of these advancements:

- User Adoption Rates: X-ray vehicle scanners comprised over 40% of the global vehicle scanner market by 2024. Nearly 900 X-ray scanners were reported to be installed at key border checkpoints worldwide by mid-2023, indicating robust global adoption.

- Effectiveness: Companies implementing X-ray systems have significantly improved operational efficiency. For instance, inspection times were reduced from 45 minutes to under 20 minutes due to the introduction of these technologies. In the automotive industry, over 35% of manufacturers report using X-ray inspection tools for enhanced defect detection, achieving higher accuracy compared to traditional inspections.

- User Satisfaction: The ability of X-ray systems to identify various materials with minimal false alarms has led to greater user satisfaction. This versatility in application ensures enhanced security and operational efficiency, thus fostering trust among transportation agencies and service providers.

- Alignment with Current Technologies: Integration with AI and digital advancements has positioned X-ray inspection systems as essential tools within modern transportation frameworks. More than 60% of manufacturers are now emphasizing AI-enabled tools to enhance detection accuracy, thus signifying a shift towards smarter, more advanced transportation inspection methodologies. Furthermore, the rise of electric vehicles and advanced driver-assistance systems necessitates precise inspections, further driving the adoption of X-ray technologies.

As Ontario implements X-ray inspection technology for commercial vehicle inspections, these trends reflect a broader movement towards enhanced safety and efficiency in transportation compliance. By leveraging advanced X-ray systems, Ontario is not just embracing innovative technologies but is also committing to a safer future for road transport.

Addressing Driver Concerns Regarding X-ray Inspection Technology

As Ontario progresses with the introduction of X-ray inspection technology, drivers may have several concerns related to this modernization of commercial vehicle inspections. It is vital to address these apprehensions to foster understanding and acceptance of the new procedure.

Exiting Vehicles for Inspection

One of the primary concerns for drivers is the requirement to exit their vehicles during the scanning process. While this may be seen as inconvenient, it is essential to understand that this step is crucial for safety and efficiency. Drivers can expect a streamlined process that minimizes overall wait times while ensuring thorough inspections. With X-ray technology, the actual scanning process is rapid and efficient, typically taking less time than traditional methods, contributing to quicker returns to the road.

Impact on Routine and Scheduling

Drivers often have tight schedules; any delay can have a ripple effect on their deliveries. The implementation of X-ray technology is designed to enhance, not hinder, operational efficiency. The inspections are expected to be completed swiftly, allowing drivers to maintain their schedules more effectively than with previous inspection methods.

Privacy and Safety Concerns

Another significant concern revolves around the privacy of drivers and the safety of their cargo. Drivers may worry whether the X-ray technology could expose sensitive information or personal belongings inside the vehicle. It is important to communicate that X-ray inspections are non-intrusive and focused solely on the structural integrity and safety of the vehicle without breaching personal privacy. These scans are conducted in compliance with safety regulations, ensuring that the process protects both the drivers’ privacy and their cargo.

Overall Experience During Inspections

The implementation of this technology represents a shift towards more advanced and effective inspection processes. As drivers adapt to these changes, the experience is expected to become more efficient and less stressful. The Ontario Transportation Ministry is committed to ensuring that the transition to X-ray technology is accompanied by clear communication and support, helping drivers feel secure and informed throughout the inspection process.

Conclusion

In summary, adopting X-ray inspection technology in vehicle inspections is crucial for improving efficiency, safety standards, and regulatory compliance. This technology changes how inspections are done and strengthens the commitment to public safety in transportation. The deployment of X-ray inspection technology marks a pivotal advancement in Ontario’s approach to commercial vehicle safety, reinforcing the benefits of efficiency, safety, and compliance. This innovative technology has proven to enhance inspection efficiency, ensure high safety standards, and strengthen regulatory adherence in the transportation sector. By allowing for timely and thorough inspections, X-ray technology ensures early detection of potential issues, confirming that all vehicles on the road meet strict safety criteria. The proactive commitment of the Ontario Transportation Ministry to integrate this cutting-edge technology underscores an unwavering focus on public safety, while actively engaging with drivers to address their concerns about the scanning process reflects a dedication to transparency and trust. The future of transportation safety looks brighter, promising enhanced compliance and an enduring commitment to community well-being.