Across logistics, construction, fleet management, and food & beverage distribution, launching a box truck operation hinges on disciplined budgeting and scalable planning. Startup costs vary with the business model, asset age, geography, and regulatory environment. This guide distills the five core cost domains every executive should quantify: truck purchase and financing, licenses and compliance, insurance, technology and equipment, and operating capital. By framing each domain with practical ranges and decision criteria, executives can forecast total cost of ownership, compare financing options, and build a budget aligned with service level commitments. Each chapter ties directly to the overarching objective: enable a funded, compliant, and resilient entry into local and regional delivery markets—whether pursuing full-truckload capacity, mixed operations, or targeted industrial services. The result is a holistic view that supports strategic decisions, risk mitigation, and a clear path toward scalable growth for logistics and fleet operations teams.

Paying for the Box: Truck Purchases and Financing in a Box Truck Startup

Buying the truck is the centerpiece of any box truck startup, but it is not the only line item that shapes the first-year financial reality. The decision to acquire a box truck—new or used—drives not only the initial price tag but also the financing terms, insurance premiums, and the rhythm of cash flow you can sustain as you grow. In practical terms, the cost floor sits around the vehicle itself, yet the way you finance and outfit that vehicle will determine how quickly you can scale, how reliably you can meet client deadlines, and how resilient you remain when the market hits a rough patch. The numbers vary widely depending on model choice, truck size, and the presence of add-ons like refrigeration, lift gates, or other specialized equipment. A typical mid-size 16- to 26-foot box truck can be a practical starting point for local or regional work, and the price range for this tier of asset is where most first-time owners anchor their financial planning. The market shows a broad spread: some buyers pursue a new truck costing around fifty thousand to eighty thousand dollars, while others start with a well-kept used unit that could be in the twenty-five to forty thousand-dollar neighborhood. It’s not unusual to encounter even broader extremes in certain regions or when buyers chase niche features.

Financing complicates the picture in a healthy way because it reframes the decision from “What can I pay today?” to “What can I service monthly without starving the core operations?” Lenders evaluate credit, equity, and the realistic earning power of the business plan. In general, you’ll find loan terms spanning roughly three to seven years, with interest rates that reflect your credit profile and the lender’s risk assessment. A ballpark range often cited by lenders runs from about five to fifteen percent, though strong financials or prior trucking experience can nudge rates lower. A practical up-front cash requirement for new trucks typically sits between ten and twenty percent of the purchase price. On a new truck priced at sixty thousand dollars, that means you may need six thousand dollars as a down payment. If you stretch toward a higher-priced unit or add features, the down payment could rise accordingly. For a used truck, the down payment is often smaller, but the risk of maintenance costs rises alongside the long-term depreciation curve.

The core equation is simple: the vehicle gets you the revenue, but the financing structure determines how much of that revenue needs to cover debt service, insurance, maintenance, and fuel before you reach profit. The more favorable the financing terms—lower rates, longer amortization, and manageable down payments—the more quickly you can reinvest in growth, hire drivers, or expand the fleet. It’s common to see a blended approach: a primary truck financed with traditional debt, plus a small reserve used to cover essential startup costs like licensing, insurance, and basic technology. In this context, a new truck’s higher upfront price may be offset by lower maintenance risk and a longer-term depreciation strategy, while a used truck’s lower price brings quicker entry but sharper attention to ongoing upkeep and potential downtime.

Beyond the vehicle itself, several core startup costs ladder up quickly. You’ll need to secure a USDOT number, which is a straightforward regulatory step but a costly one in terms of time and fees. State registrations and permits typically add a few hundred dollars, depending on where you operate. Insurance stands as one of the most consequential ongoing costs: commercial auto coverage for a box truck tends to range from roughly two thousand to five thousand dollars per year, though premiums can be higher if the shipper cargo is high-risk or your driving record has blemishes. The cost of technology and equipment also matters. A reliable GPS tracking system, basic onboard diagnostics, and dispatch software can run from about one thousand to three thousand dollars upfront. Then there are the safety and auxiliary items—loading ramps, cargo nets, padding, tarps, and tie-downs—that could add another five hundred to fifteen hundred dollars.

All of these expenses accumulate into a practical startup capital requirement. Industry guidance often suggests setting aside three to six months of operating expenses upfront to cover fuel, maintenance, driver wages if needed, and marketing as you land first customers. Depending on your location and operating model, that reserve could realistically fall in the ten thousand to thirty thousand dollar range or higher. When you combine the truck purchase, financing costs, licensing, insurance, and basic outfitting, you begin to see a distribution of early cash needs that rises with your ambition: a modest, low-risk entry might cluster around forty thousand to sixty thousand dollars; a more ambitious, fully equipped setup could push toward seventy thousand to a hundred thousand dollars; and a multi-truck, tech-enabled operation with a robust team can easily venture into the hundred-fifty thousand-dollar territory or more.

The timing of purchases and the scale of your ambitions warrant a thoughtful strategy. Many operators start with a single, reliable truck to prove the model, then gradually scale as revenue solidifies. This staged approach aligns well with how financing can be structured and how cash flow evolves. It also offers a buffer against market fluctuations. A growing e-commerce landscape has boosted demand for flexible, local delivery options, which creates opportunities for a careful entrant to secure repeat clients while maintaining lean overhead. This is not a race to accumulate assets, but a process of aligning asset value with actual operating capacity and consistent demand. To gain perspective on broader industry dynamics and practical startup planning, consider a trusted, practical guide that frames the process for newcomers; you can explore a related overview at start-trucking-business-2026, which offers context on how other new entrants time their moves and calibrate initial costs.

When you zoom in on the numbers, the cost picture also helps you plan the financing package that makes sense for your personal and business credit profile. If you opt for a new truck with modern features in the sixty-thousand-dollar range, expect a down payment near six thousand dollars, and a loan of the remaining balance spread over five or six years. Monthly payments might fall in the four hundred to eight hundred-dollar neighborhood, excluding insurance and maintenance, which should be budgeted separately. A used truck in the thirty-thousand-dollar range can lower the cash outlay to roughly three thousand dollars down, with monthly payments reflecting the smaller principal. The trade-off is higher maintenance risk and potentially shorter remaining life. In either case, the insurance envelope will be a steady line item to monitor year over year, with premiums sensitive to driving history, cargo type, coverage limits, and deductibles. A prudent practice is to lock in at least a baseline coverage that protects against the most common losses—bodily injury, property damage, and cargo—to avoid gaps that could complicate operations or shut down a contract after a claim.

The broader budgeting exercise also includes the cost of regulatory compliance and operational readiness. A dedicated business banking relationship can simplify the financing process, while a reliable insurer can help you navigate the nuances of commercial auto coverage and cargo liability. The total initial investment, according to typical scenarios, can be described as a ladder of options: a low-end trajectory with a used truck, minimal technology, and no employees might hover in the forty to sixty thousand-dollar range; a mid-range path with a new truck, basic technology, and standard insurance sits around seventy to one hundred thousand dollars; and a high-end path with multiple trucks, advanced software, and team-based operations exceeds one hundred fifty thousand dollars. Each tier carries its own rhythm of cash inflows and outflows, and each demands disciplined budgeting and a clear plan for how capacity, scheduling, and client relationships will translate into predictable revenue.

For those who want a grounded financial framework, the Small Business Administration offers extensive guidance on loans, down payments, and financing structures that are common in the small fleet segment. This external resource can be a useful companion as you compare offers and model your first twelve months. In practice, your readiness depends less on a single number and more on how well you can translate a realistic revenue forecast into a sustainable debt service plan. The box truck startup, once you commit to a purchase and a financing path, becomes a measurable set of actions: secure the authority, acquire the asset or lease it, outfit it with essential gear, obtain price-appropriate insurance, and establish a disciplined cash flow model that balances debt service with operating needs. The journey to profitability hinges on striking that balance early, while remaining adaptable to the evolving needs of clients and the tightening or loosening of credit markets.

For a broader financial framework and further reading on financing your business, consult the U.S. Small Business Administration’s resources here: https://www.sba.gov. This external reference provides a structured overview of small-business loans, down payment considerations, and typical repayment horizons that can help you populate your own cash flow projections for the initial year of operation.

Licenses, Permits, and Compliance: Building the Legal Foundation of Your Box Truck Startup

A box truck business is as much a legal venture as it is a logistical one. The licenses, permits, and ongoing compliance requirements establish the framework within which every mile of operation occurs. For a new operator, these costs are real and sometimes overlooked, yet they determine when you can hit the road and how smoothly your operation can scale. The cost picture starts with local business licensing and builds outward to federal compliance, touching every state you plan to serve. Understanding this landscape helps you budget with clarity and avoid delays that can stall a launch you have already planned for months. On the simplest level, you will need a basic business license from your city or county. Typical annual fees range from fifty to a few hundred dollars, depending on local regulations and the business structure you adopt. That modest upfront investment unlocks the ability to register your entity, open a business bank account, and secure appropriate insurance. It also signals to customers and suppliers that you operate with legitimacy, which can affect everything from credit terms to the ability to bid on local jobs.

Beyond the local level, the Federal Motor Carrier Safety Administration (FMCSA) applies when your operation involves commercial vehicles that meet or exceed certain weight thresholds. If you intend to run as a motor carrier in interstate commerce, you must obtain an FMCSA operating authority, commonly referred to as an MC number. The typical fee for a single carrier is around three hundred dollars per year. This is not merely a line item; it is a regulatory gate that governs who can legally transport freight for others across state lines. In parallel, you may need a U.S. Department of Transportation (DOT) number if your activities cross state lines and your vehicle weight exceeds ten thousand pounds. Unlike the FMCSA registration, obtaining a DOT number is free through the FMCSA portal, but it often accompanies other compliance obligations that add to your overhead. The combination of MC authority and a DOT number marks you as a legitimate interstate carrier and triggers additional recordkeeping and safety requirements that follow you as you grow.

State-specific permits and registrations are the next layer. These are the most variable costs you will encounter, reflecting differences in regulatory philosophy, tax structures, and enforcement intensity. For example, some states impose carrier permits or annual registration fees tied to vehicle size or weight class, while others bundle compliance into broader vehicle registration. Fees can range from a few dollars to several hundred dollars per year, but the most important takeaway is that you should budget for these costs as part of your startup plan. If you operate in a state with a comprehensive carrier-permitting regime, you might see a wider range of fees depending on the size of your fleet, the type of cargo you plan to haul, and the routes you intend to serve.

A controlled driver’s license (CDL) is another cost consideration that can influence your overall capital needs. If you plan to drive the box truck yourself, and the vehicle weight classification requires it (often over twenty-six thousand pounds gross vehicle weight rating), you will need a CDL. Licensing costs vary by state but typically fall in the one hundred to three hundred dollar range for testing and license issuance. Even if you don’t drive, a CDL can be a prerequisite for certain supervisory or fleet management roles, depending on your setup. The key point is to align licensing decisions with your planned operations so you don’t pay for credentials you won’t use, while ensuring you have the right credentials in case you decide to expand responsibilities to in-house driving.

Insurance is the ongoing linchpin of compliance. Commercial auto insurance for a box truck is mandatory and tends to be one of the largest recurring expenses in this category. Premiums depend on several factors, including your coverage level, cargo type, driving history, and the insurability of your routes. Typical annual premiums can range from about one thousand to five thousand dollars or more for basic liability and collision, with higher costs if you carry valuable or hazardous cargo, or if you operate with multiple drivers or vehicles. When you price this, you should factor not only the premium itself but the potential insurability gaps you may encounter as you scale, because cost can rise with fleet expansion or with changes in risk exposure.

Safety and regulatory compliance require more than insurance and licenses. Most box truck operators must implement a robust set of logs, inspections, and maintenance records to comply with federal and state requirements. The modern ecosystem often includes electronic logging devices (ELDs), trip and duty logs, and maintenance scheduling software. These tools help you stay transparent with regulators and the customers you serve. The up-front and ongoing costs for compliance software and hardware can be modest—roughly twenty to a hundred dollars per month for basic logging and inspection systems, with higher-end suites offering dispatch integration, maintenance reminders, and real-time GPS tracking. Add the tangible costs of physical safety gear—loading ramps, tie-downs, tarps, and wheel chocks—and the picture becomes clearer. The initial investment for these items can be five hundred dollars to a few thousand, depending on how fully you equip your operation at the outset.

Compliance extends into ongoing recordkeeping, audits, and potential inspections. Even if you begin with a lean operation, you should plan for occasional regulatory checks and the administrative time required to maintain filings, insurance proofs, and updated registrations. In practice, this means budgeting for administrative support or time you or a partner will dedicate to keeping your paperwork current. While the FMCSA and state agencies publish specific requirements, the real-world workflow often involves periodic reviews of driver qualification files, vehicle maintenance logs, insurance certificates, and route records. The cost here is not just money but time, which translates into opportunity costs if mismanaged.

In total, the initial costs tied to licenses, permits, and compliance can be modest or meaningful depending on location and business design. A commonly cited range for start-up readiness sits around five hundred to two thousand dollars for licenses, permits, and basic compliance tools, with higher amounts when you add more sophisticated regulatory software, multiple drivers, or a larger fleet. That said, these expenditures are foundational. They enable you to operate legally, access carriers and customers, and protect yourself from regulatory penalties that can eclipse upfront investments in a single misstep. When you plan, you should map these fees against your anticipated operating model. A single-truck, owner-operator setup will look distinctly different from a small fleet with a dedicated dispatcher and a compliance manager. The intention is to create a budgeting baseline that reflects your intended scale while leaving a cushion for the inevitable regulatory changes that accompany a growing enterprise.

To illustrate how these pieces fit into a broader budgeting exercise, consider a startup that aims to run a single box truck with light local delivery and occasional cross-border work in the future. The city or county license sits at the low end of the spectrum, followed by the FMCSA MC number, then the state permits—each step adding a layer of regulatory compliance that, while predictable, is not optional. If the driver is the owner and will drive the truck personally, a CDL adds another potential cost, albeit one that might be deferred until growth justifies it. Insurance, a fixed annual cost, anchors the ongoing financial plan and should be secured before the truck hits the road. The compliance tools, while incremental in annual dollars, deliver exponential value in reliability, safety, and the ability to contract with reputable clients. In this sense, licensing, permitting, and compliance costs become investments in reliability and market access rather than mere line items on a startup spreadsheet.

For operators who want a quick navigational cue through this regulatory maze, a practical tip is to view compliance as a risk management and customer-confidence mechanism rather than a hurdle. A simple, disciplined approach—documenting a project plan for licenses, scheduling timely renewals, investing in essential compliance software, and maintaining clean records—keeps you well ahead of the curve as you add trucks, drivers, and routes. When you are ready to explore the regulatory landscape in greater depth, you can look to industry-focused regulatory resources for context-specific guidance. For a concise overview of regulatory considerations during critical periods, see Regulatory relief during winter storms trucking.

Finally, stay aligned with official guidance. For official, up-to-date information tailored to your situation, consult the FMCSA portal and related regulatory resources. An authoritative starting point is the FMCSA site, which houses the most current rules, fees, and forms you will need as your operation grows: https://www.fmcsa.dot.gov.

Insuring Momentum: Cost, Coverage, and Risk Management in Launching a Box Truck Business

Starting a box truck venture is as much a test of financial discipline as it is of operational grit. The sticker price of the truck is only part of the equation. A careful eye on insurance, risk controls, and the way those costs interact with your growth plan can decide whether the business launches smoothly or stumbles in the first year. When you map the path from zero to a single active rig, you must think in layers: the upfront investment in equipment, ongoing protection against loss, and the strategic measures that keep premiums from swallowing your margins. Insurance and risk management are not afterthoughts; they shape every decision you make about truck choice, routes, staffing, and how you demonstrate reliability to customers and lenders alike.

One of the clearest truths about starting a box truck business is that insurance is a major recurring expense, and it scales with the scope of your operation. In practical terms, the most common coverage you’ll need encompasses four pillars: commercial auto, general liability, cargo, and workers’ compensation where you have employees. Industry ranges suggest commercial auto insurance for a single box truck averages about $1,500 to $3,000 per year. General liability tends to run about $500 to $1,500 annually, covering third‑party injuries or property damage that can occur during a delivery. Cargo insurance, essential if you’re moving valuable goods or items with high value per shipment, typically runs $100 to $500 per month. Workers’ compensation is a fixed cost only if you hire drivers or other staff; for a small operation, this could be a few thousand dollars per year, depending on the state and job classifications. Taken together, these numbers illuminate the ongoing annual burden per truck and how quickly it compounds as you scale beyond a single vehicle.

Several factors explain why premiums vary so widely. The cargo you carry affects risk exposure; high-value or hazardous goods command higher coverage and often higher premiums. The geographic footprint of your routes matters as well: urban environments with dense traffic and higher theft risk push up premiums. Coverage limits show up in the math too. Many operators settle on a liability limit around $1 million, a level that offers protection without forcing crippling premiums. Your driving history and the age and condition of the vehicle also feed into the quotes. A newer, well‑maintained box truck with a clean driving record will typically attract more favorable terms than an older rig with higher mileage and a record of incidents.

Beyond the numbers, the most meaningful factor is how you manage risk day to day. The higher your baseline controls, the less you pay in claims and downtime, which in turn nudges down insurance costs over time. Industry insights frequently point to a powerful correlation: robust risk management can yield meaningful reductions in both claims frequency and operational downtime. In practice, this means that disciplined practices—sound driver onboarding, ongoing safety training, proactive maintenance, and clear, enforceable contracts—do more than protect against losses. They also improve your cost of capital, your ability to land favorable terms with lenders, and your capacity to weather market shocks.

To build that protective shield, start with people. Driver screening and training lie at the heart of safe, reliable service. Verifying qualifications, checking motor vehicle records, and ensuring that every driver understands the company’s safety expectations lowers accident risk and, by extension, reduces the probability of costly insurance claims. Then come the tools that enable safer, smarter operations: telematics and GPS tracking systems that illuminate route efficiency, driver behavior, and theft deterrence. Real‑time visibility helps you audit performance, reward good habits, and address riskier patterns before they become expensive incidents. Regular enforcement of maintenance schedules—servicing the engine, brakes, tires, and electrical systems at specified mile intervals—prevents breakdowns that not only cost money in repairs but can interrupt revenue during peak periods. A predictable maintenance cadence also supports your insurance profile, because well‑maintained equipment is viewed as lower risk.

Contracts and customer agreements round out the shield. Clear terms about delivery windows, liability limits, and payment timelines reduce the likelihood of disputes that can morph into costly claims or extended downtime. For many operators, it’s also worth drafting emergency response plans. If a breakdown, accident, or cargo loss occurs, knowing who calls whom and what steps to take keeps the operation moving and minimizes damage to customer relationships. A thoughtful approach to cyber risk also matters. If you run a digital dispatch platform or collect customer data, you should implement basic cybersecurity measures to safeguard information and keep operations from grinding to a halt because of a data breach. Even modest protections can bolster your insurance posture by lowering exposure in the eyes of underwriters.

The numbers tied to risk are not abstract. They shape monthly cash flow and the feasibility of adding trucks. For a starter with one truck, the initial outlay can include the purchase or lease price of a 16– to 26‑foot box truck, which commonly ranges from $40,000 to $70,000 when buying new. Used trucks exist in a more forgiving price band, typically $20,000 to $40,000, though they carry higher maintenance risk and possibly higher insurance costs. Add licenses, registrations, and inspections, and you begin to see how insurance and risk management frame the affordability envelope of the business. The recurring costs of insurance and safety programs must be reconciled with projected revenue, and that reconciliation hinges on a realistic plan for growth. Understanding that 3–6 months of operating expenses is a prudent cushion—covering fuel, maintenance, driver wages if applicable, and marketing—helps you withstand early volatility. In practice, this operating capital buffer might translate to roughly $10,000 to $30,000 or more, depending on the scale of your initial operation and your local labor market.

As you design your startup and its funding plan, consider the strategic value of risk management investments beyond the minimum compliance requirements. Investments in good telematics, comprehensive driver training, and routine maintenance can yield returns in the form of lower insurance premiums over time, fewer downtime days, and higher customer satisfaction. These are not merely protective measures; they are productive assets that improve reliability and set the stage for scalable growth. When you articulate your business plan to lenders or investors, you can point to a structured risk program as a differentiator—evidence that you are pursuing sustainable profitability rather than chasing a quick, fragile foothold.

For readers exploring the practical specifics of risk controls, one practical reference is the broader field of cargo security and loss prevention. Implementing a focused set of steps to deter theft—such as securing cargo with tamper‑evident seals, locking compartments, and routine audit trails—can materially reduce exposure. For a concise discussion on risk‑aware strategies that help keep insurance costs in check, see cargo theft reduction strategies. By combining disciplined personnel practices with intelligent technology and clear customer terms, you create a resilient base that supports not only safer operations but also more favorable insurance terms over time.

This integrated approach—rooted in disciplined people practices, reliable processes, and prudent capital planning—forms the backbone of a viable, scalable box truck business. Insurance costs will remain a significant line item, but they become manageable when paired with aggressive risk reduction and a deliberate, stepwise growth plan. The economics favor starting small: a single truck with a tightened risk program, followed by measured expansion as demand validates the model and as your cash reserves and credit capacity strengthen. In that path, insurance is not the gatekeeper that halts progress; it is a risk management instrument that, used wisely, protects momentum and underwrites the confidence of customers,

External resources can provide practical frameworks to support this approach. For a hands-on, step-by-step blueprint that aligns with today’s market realities, see How to Write a Box Truck Business Plan: A Step-by-Step Guide (2026).

External resource: How to Write a Box Truck Business Plan: A Step-by-Step Guide (2026)

Tech, Trucks, and the First Wallet: Navigating Equipment and Setup Costs to Launch a Box Truck Business

Every box truck venture begins with a core question that echoes through every decision afterward: how much will it cost to get off the ground? The answer hinges on a tight mix of vehicle price, regulatory footing, and the tech that makes a single truck sing or a fleet hum. In this chapter, the focus is on Technology, Equipment, and Setup—the elements that convert a pile of potential into a measurable, operating business. The numbers can look intimidating at first, but they are also practical, actionable, and highly dependent on scale, risk tolerance, and your chosen business model.

First, the backbone of any box truck operation is the vehicle itself. Vehicle acquisition dominates upfront cost and sets the pace for the rest of the budget. New box trucks carry a hefty price tag, typically in the range of forty thousand to eighty thousand dollars per unit. A used box truck, while gentler on the initial wallet, carries its own calculus: twenty thousand to fifty thousand dollars depending on age, mileage, and condition. These ranges reflect the current market dynamics of 2026, when buyers weigh durability and residual value as much as immediate cash outlay. The choice between new and used will cascade into financing terms, insurance costs, maintenance expectations, and depreciation benefits, so it’s worth examining early and candidly with lenders or a trusted advisor.

Beyond the chassis and shell, licensing and regulatory setup create a structural layer that you cannot skip. An FMCSA operating authority, often necessary for a single-carrier operation, costs modestly—typically a few hundred dollars—while state registrations and permits add a little more, depending on where you operate. The cost guidance here emphasizes that compliance is not a one-time hurdle but an ongoing budget item. You’ll also need commercial auto insurance for the vehicle itself, which runs roughly two thousand to six thousand dollars per year per truck, with cargo and hauler’s liability insurance providing additional protection that can add roughly one thousand to three thousand dollars annually. The exact mix depends on coverage levels, the value of the cargo, and the driver roster. Getting the right coverage is crucial not only for protection but for securing favorable financing and reliable operations as you grow.

Technology and fleet management are the next major expense layer, and they are the most impactful on daily efficiency and customer experience. A basic but robust setup typically begins with GPS tracking devices, priced roughly one hundred to three hundred dollars per unit. Fleet management software, which can dramatically improve routing, maintenance scheduling, and driver behavior monitoring, usually runs about fifty to one hundred dollars per month per vehicle if you opt for a subscription model. If you anticipate needing a custom app or more extensive communications for customers and drivers, upfront software development costs can range from about one thousand to ten thousand dollars, depending on complexity and integration with dispatch systems. Then there are the safety and logistics extras—loading ramps, tie-downs, tarps, and other essential safety gear—that collectively add several hundred to a couple thousand dollars at setup.

Maintenance and the ongoing operational backbone are often underappreciated until a vehicle is parked for the day with a warning light on the dash. A prudent maintenance fund for each truck—roughly five hundred to one thousand dollars per month—helps cover routine wear items, inspections, and tire care, reducing unexpected downtime. Fuel consumption is another large variable: monthly fuel outlays can range from one thousand to two thousand dollars per truck, depending on mileage, routes, and fuel prices. Storage or workshop space, whether it’s a small garage or a secure yard, typically costs five hundred to two thousand dollars per month depending on location and access. When you add up maintenance, fuel, and storage, you begin to see how the monthly operating rhythm is shaped not just by miles driven but by the efficiency of your maintenance and logistics planning.

All these pieces—vehicle price, licensing, insurance, technology, and ongoing operating costs—must be considered together to form a realistic startup budget. One-truck operations that begin with a used box truck and minimal technology can land in a broad range roughly around thirty-five thousand to seventy thousand dollars in initial startup costs. That reflects the cheaper entry with a used vehicle, lean tech adoption, and a modest cushion for working capital. If you scale to a single newer truck with fuller insurance coverage and a more capable tech stack, you’re looking at the mid to upper end of that band, well into the seventy-thousand to one-hundred-thousand-dollar territory. For more ambitious setups—multiple trucks, higher-grade software, and more comprehensive coverage—the startup figure can easily exceed one hundred thousand dollars and stretch toward the higher hundreds, especially if you pursue aggressive growth plans or require specialized cargo insurance.

A practical way to think about setup costs is to stage them as a sequence: secure the vehicle, establish baseline compliance and insurance, and then layer in the technology and maintenance discipline that will sustain reliability. Even this simple sequencing has a ripple effect on cash flow. Vehicle financing terms will affect monthly obligations, while the choice of telematics and software can alter dispatch efficiency and fuel usage, which in turn influence fuel contracts, maintenance schedules, and driver wages if you hire. The math matters not just for the first quarter but for the first year, because a lean but well-planned setup can translate into faster break-even points and greater resilience when demand fluctuates.

The flexibility of the box truck model matters here. The industry has shown sustained growth, driven by e-commerce and the demand for flexible, local delivery options. That growth underscores a practical truth for new entrants: starting small and scaling with demand can manage financial risk while you build reputation and routes. The decision to start with a single used truck or to bet on a newer single unit or even a tiny fleet hinges on risk tolerance, access to capital, and local market conditions. The budgeting approach should also incorporate a modest line for marketing and customer acquisition, as new entrants often need to prove reliability and communication channels to shippers and brokers. A well-chosen technology stack can amplify the impact of a modest fleet by delivering real-time updates, efficient routing, and proactive maintenance alerts that prevent costly breakdowns and missed pickups.

To keep the planning grounded, consider a lightweight, practical linkage to broader strategic guidance: investing in people and processes as you scale. The long-term success of a truck operation rests as much on the people you hire and how you develop them as on the hardware you buy. See the discussion on investing in people for trucking fleets for concrete ideas on building a capable team and aligning training with service quality. investing-in-people-key-to-truckings-success

As you weigh these numbers, remember that location and financing channels can alter the bottom line. Local insurance rates, permit fees, and even the cost of storage space can shift with regional demand, regulatory environments, and the availability of qualified drivers. It’s also important to plan for the unexpected. Build a conservative contingency into your initial capital so you don’t hit a cash crunch the moment a truck needs an unplanned repair or a shipment is delayed. A practical approach is to reserve enough capital to cover three to six months of operating expenses, including fuel, maintenance, driver wages if applicable, and marketing. This cushion helps you weather the early months when revenue is still ramping and the learning curve is steep.

For readers who want a more concrete comparative view, the one-truck scenario with a used vehicle and basic tech provides a baseline. If you decide to expand later, you’ll re-run the budget with higher insurance costs, more complex technology, and the possibility of financing multiple units. The interplay between upfront investment, ongoing costs, and revenue potential defines the path to profitability. You’ll need a clear plan for dispatch, maintenance, and customer communication to turn these costs into a reliable service and a sustainable business. The practical takeaway is straightforward: map your needs to a realistic equipment and tech footprint, secure solid regulatory footing, and protect cash flow with a disciplined maintenance and reserve strategy. The more integrated your approach—where dispatch, maintenance, and driver management talk to each other—the smoother the climb from startup to scale.

External reading can complement this chapter, especially for broader startup guidance and market context. For deeper dive into startup planning and the economics of trucking ventures, see an external resource on trucking startup planning: https://www.shopify.com.hk/blog/start-trucking-business-2026

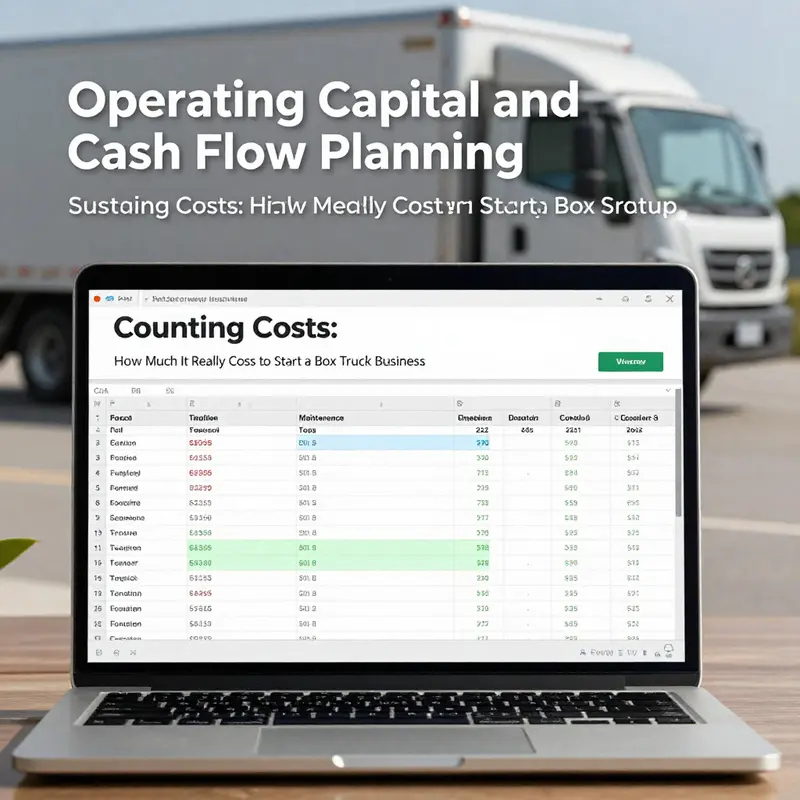

Crunching the Startup Tab: Operating Capital and Cash Flow Planning for a Box Truck Venture

Launching a box truck business often feels like a step into a ledger, where every line item maps to a real-world decision about risk, timing, and the ability to stay solvent while you grow. The sticker price of a truck is only part of the story. The real margin of safety lies in how you manage operating capital and forecast cash flow as you move from launch to steady operations. In practical terms, the initial investment typically covers not just the vehicle itself but a set of ongoing costs that can stretch the startup period from a few weeks into several months. Because the market for local and regional deliveries has grown on the strength of e-commerce, the opportunity is real, but the financial runway must be planned with discipline and clarity from day one.

The most visible upfront cost is the vehicle purchase or lease. A brand-new box truck offers reliability and longer life, but the price tag is substantial. A new box truck can run roughly in the range of forty to seventy thousand dollars, while a used unit may cost twenty to forty-five thousand, depending on age and condition. Leasing options exist as well, and they reduce a large upfront outlay at the cost of ongoing payments. Either path requires a clear view of how long you will operate the truck before it starts to contribute positively to cash flow.

Insurance sits alongside the vehicle cost as a non-negotiable ongoing expense. Commercial auto coverage for a box truck generally falls in the low thousands per year, with the exact premium depending on coverage levels, the cargo you carry, the location, and the driver history you bring into the business. This is not merely a defensive cost; it connects directly to your ability to dispatch and win customers who demand reliable risk management. Then there are the licenses and permits—CDL-related requirements, business licenses, and any local registrations. While these fees vary by state, planning for a few hundred dollars on the low end is prudent, with the total potentially higher if multiple registrations or special permits apply to your service model.

Fuel, maintenance, and tires form the core of ongoing operating costs that you will feel every month. Budgeting for fuel and regular maintenance is essential because these are the predictable drains that can accelerate cash burn during ramp-up. The common range you’ll encounter is a few hundred dollars per month for routine maintenance plus a variable fuel bill that follows miles and load profiles. A practical approach is to forecast fuel and maintenance as a combined monthly target—often in the five- to six-figure annualized range when you include oil changes, tire replacements, and unexpected repairs. It’s not glamorous, but it is the engine that keeps the wheels turning.

Technology and equipment add another layer of startup cost but are critical to efficiency and margins. GPS tracking, dispatch software, and basic fleet management tools can require up-front investments in the low thousands, with ongoing subscription costs that you should budget as a monthly line item. Loading equipment—dollies, ramps, tie-downs, and safety gear—also sits in the initial outlay, with a few hundred to a few thousand dollars allocated depending on the scale of your operation. Smart technology yields a tighter dispatch cadence and better asset utilization, which, in turn, supports healthier cash flow over time.

Marketing and customer acquisition are often overlooked in early cost projections, yet they are essential to reaching a sustainable revenue level. A modest investment in branding, a simple website, and outreach campaigns can set the stage for a consistent pipeline of jobs. In the early stages, you may invest a smaller amount here, but you should still reserve funds to attract your first customers and demonstrate reliability in a competitive market.

Beyond these line items, operating capital planning is where the true discipline matters. The rule of thumb you will hear most often is to hold three to six months of operating expenses in reserve before you launch. That cushion helps cover fuel, routine maintenance, driver wages if you hire, and the initial push required to establish your customer base. In practice, the total startup investment frequently lands in a broad band—from about thirty thousand dollars on the low end to well over a hundred thousand dollars for a more ambitious, multi-truck setup. The exact number depends on your business model: whether you’re pursuing full truckload or less-than-truckload work, whether you buy new or used equipment, and how lean or aggressive your staffing and technology choices are.

Underpinning all of this is a careful cash flow plan that translates the forecast into a reliable operating rhythm. Cash flow projections should map out the ramp-up period, recognizing that customer onboarding, negotiations, and the time it takes to secure favorable terms with shippers can stretch the period before receipts consistently cover costs. Building a forecast with monthly granularity helps you anticipate shortfalls, enabling adjustments to pricing, spending, or financing before a crunch occurs. A practical approach is to model three to six months of negative cash flow during ramp-up, followed by a more balanced or positive trajectory as new customers come online and utilization increases.

The structure of your cash flow plan should also account for payment terms and the timing of inflows. If you operate in a model where clients pay net-15 or net-30, you will need to front a larger portion of expenses during the early months. This makes the availability of a credit line or a small business loan particularly valuable as a revolving buffer. In addition, fleet-related variables—fuel price volatility, maintenance spikes, or downtime due to weather or regulatory checks—should be included in stress tests within the forecast. These are not theoretical risks; they are the kinds of shocks that tests of your capital reserves will reveal.

A smaller but real factor is how you balance growth with cash discipline. It is tempting to chase more routes and more loads, but without the working capital to fuel that growth, you can run into liquidity constraints that threaten everything from timely payroll to vehicle maintenance. That is why a robust plan includes not only reserve targets but a clear path to profitability. The plan should lay out the expected contribution margins on typical routes, the cost to acquire new customers, and the break-even point under different load factors. By anchoring decisions to a disciplined financial model, you can scale deliberately as demand grows rather than chasing a perpetual cycle of cash burn.

As you craft this framework, a mindset shift helps: treat operating capital not as a backstop but as a strategic asset. The funds you set aside are not merely safety; they are fuel for growth, a commitment to reliability, and a signal to lenders and customers that you are prepared to weather variability. It is also wise to integrate a human capital plan into cash flow thinking. Hiring drivers or contracting with trusted carriers expands capacity, but it also increases payroll and insurance exposure. A path that intertwines people strategy with financial planning—recognizing that skilled staff are a critical asset—builds resilience into the forecast. For perspective on people-centered strategies in trucking, see the ideas linked here: People-first-strategies-in-trucking.

If you need a broader framework for turning these numbers into a credible plan, remember the market context that frames startup costs and cash needs. The box truck sector has been expanding as e-commerce and local deliveries demand flexible, dependable options. A well-structured plan is not only about surviving the first year; it is about setting a path to sustainable profitability as demand compounds and scales. A comprehensive, disciplined approach to capital, cash flow, and contingency budgeting makes that path clearer and more actionable.

For a deeper dive into the overall planning process, you can consult external guidance that lays out step-by-step methods for box truck plans and financial modeling. A detailed guide on building a box truck business plan, including cash flow considerations, can be found here: https://www.shopify.com/ie/blog/box-truck-business-plan-step-by-step-guide-2026. This resource complements the internal framework by offering structured templates, assumptions, and example projections that can be adapted to your own market and model.

In sum, starting a box truck business requires more than the purchase price of the truck. It requires a disciplined capture of all expected costs, a prudent operating capital reserve, and a cash flow model that anticipates ramp-up realities. With thoughtful planning, the cash constraints that often derail early-stage ventures become navigable challenges, not roadblocks. In that sense, the numbers you assemble early are less about a single moment of launch and more about the ongoing discipline that sustains a growing, service-driven operation. And as you build, you’ll find that the bigger your reserve and the clearer your forecast, the more confident you can be in investing in the right assets, the right people, and the right customer relationships that keep the wheels turning.

Final thoughts

A box truck startup is a disciplined exercise in aligning asset purchase, regulatory costs, risk management, and operating liquidity with the intended service model. By investing in a clear cost framework—covering truck acquisition, licensing, insurance, technology, and runway capital—organizations serving logistics, construction, fleet management, or food & beverage distribution can forecast margins, secure appropriate financing, and pace growth with demand. The five-domain approach provides a reproducible budgeting template that scales from a single-vehicle pilot to a multi-truck operation, ensuring both compliance and competitive service levels while maintaining financial resilience amid market fluctuations.