In recent years, the need for modernized safety measures in the transportation sector has become increasingly critical, particularly in Ontario where commercial vehicles traverse the bustling highways daily. The introduction of X-ray inspection technology marks a significant leap forward in the realm of commercial vehicle inspections. This innovative approach not only enhances the efficiency of inspections conducted by the Ontario Transportation Ministry (MTO) but also plays a vital role in bolstering public safety.

For instance, the ability to swiftly identify undocumented cargo and illegal shipments without prolonging inspection times is crucial for effective enforcement measures. As Geoff Wood, OTA’s senior vice-president of policy, stated,

“With this latest announcement, we are entering another phase and use of this critical MTO infrastructure by adding tools necessary for enforcement to vastly expand its capabilities, including the identification of undocumented cargo and illegal shipments, which are an unfortunate reality in the industry.”

Such advancements ensure that our roads remain safe and compliant, safeguarding both the transport industry and the communities it serves. This article will delve deeper into the implications of deploying X-ray inspection technology and its expected impact on enforcement and public trust.

Effectiveness of X-ray Inspection Technology in Commercial Vehicle Inspections

Research and studies highlight the notable efficacy of X-ray inspection technology in the realm of commercial vehicle inspections, particularly in enhancing safety enforcement and significantly reducing the prevalence of illegal shipments. Here are some key findings:

- Detection of Illegal Shipments: Advanced imaging technologies, such as backscatter X-ray systems, have proven capable of identifying up to 95% of illegal shipments. This high detection rate is pivotal for safety, as these systems can effectively uncover hidden contraband, unauthorized cargo, and smuggled goods, thus playing a critical role in ensuring road safety and compliance.

- Improved Inspection Efficiency: The deployment of modern X-ray systems has transformed the efficiency of cargo verification. Certain technologies allow inspection of trucks traveling at speeds of 4 to 5 miles per hour, completing a typical scan in approximately 12 seconds. This rapid processing capability greatly minimizes wait times, consequently streamlining the overall inspection throughput.

- Innovative Detection Capabilities: Recent advancements, including cosmic ray muon tomography, have emerged as effective means for non-invasive inspections of shipping containers and trucks. By utilizing cosmic-ray muons, this method generates three-dimensional images of dense cargo, enhancing the identification process for various materials while aiding in the detection of illicit goods.

- Support from Regulatory Policies: The operational implementation of X-ray inspection technologies has been well-received by government agencies. For instance, the Ontario Ministry of Transportation (MTO) has initiated a rollout of new X-ray technology, aimed at boosting the efficacy and efficiency of commercial vehicle inspections. This initiative underscores the importance of robust enforcement measures in maintaining safety on the roads.

Collectively, these insights affirm the critical role that X-ray inspection technology plays in bolstering safety enforcement, effectively detecting illegal shipments, and enhancing the efficiency of commercial vehicle inspections. Such advancements not only ensure compliance within the transport industry but also contribute to the overarching goal of public safety and the integrity of transportation networks. Additionally, the integration of automated vehicle inspections further enhances the capabilities of this technology, streamlining inspection processes and supporting increased regulatory compliance.

X-ray inspection technology in action at a roadside checkpoint

Benefits of X-ray Technology in Vehicle Inspections

The deployment of X-ray technology in vehicle inspections offers numerous benefits that enhance operational efficiency, safety, and regulatory compliance. Here are the specific advantages:

-

Enhanced Efficiency

- Rapid Non-Invasive Inspections: X-ray technology facilitates quick inspections without needing to unload cargo. Trucks can undergo scanning while in motion, significantly reducing inspection times.

- Streamlined Processes: The technology allows inspectors to assess vehicles swiftly, improving overall throughput at checkpoints. For instance, scans can take as little as 12 seconds per vehicle, minimizing delays.

-

Improved Safety Standards

- Minimized Physical Contact: By utilizing X-ray inspections, there’s reduced need for inspectors to come into direct contact with potentially hazardous materials, lowering health risks.

- Comprehensive Detection Capabilities: The technology can identify hidden cargo and contraband accurately, ensuring that unsafe or illegal shipments are intercepted without compromising safety.

-

Identification of Illegal Shipments

- Detection of Concealed Goods: X-ray systems are adept at revealing hidden items such as stolen vehicles, unauthorized cargo, and smuggled goods, thereby enhancing enforcement activities.

- Proven Efficiency in Law Enforcement: Instances such as the Canada Border Services Agency’s deployment of mobile X-ray scanners resulted in the interception of over 1,300 stolen vehicles, showcasing the critical role of X-ray in crime prevention.

-

Regulatory Compliance and Policy Impact

- Support for Enhanced Regulations: The adoption of X-ray technology aligns with Ontario’s commitment to robust transportation safety regulations, reinforcing legal compliance among commercial vehicle operators.

- Advocacy for Nationwide Adoption: Organizations like the Ontario Trucking Association advocate for expanded use of this technology, promoting safety and uniform enforcement standards across Canada.

In conclusion, X-ray technology in vehicle inspections not only enhances efficiency and safety but also plays a pivotal role in the identification of illegal shipments, thus supporting stringent regulatory frameworks in Ontario’s transportation sector. With the ongoing advancements in this field, we can anticipate a future where vehicle inspections are even more effective and safer for all.

Comparison Table: Traditional Inspection Methods vs. X-ray Inspection Technology

| Criteria | Traditional Inspection Methods | X-ray Inspection Technology |

|---|---|---|

| Time Efficiency | Longer inspection times, requiring manual checks and unloading cargo | Quick scans allowing for vehicles to remain loaded, typically completed in 12 seconds |

| Detection Accuracy | Variable accuracy, dependent on inspector skill and thoroughness | High accuracy, identifying up to 95% of illegal shipments |

| Safety Outcomes | Increased inspector contact with potentially hazardous materials | Reduced physical contact during inspections, minimizing health risks |

| Operational Impact | Potential for traffic delays and congestion | Streamlined inspection processes, lowering wait times |

| Regulatory Compliance | May rely on less efficient, outdated methods | Enhances compliance through advanced detection capabilities |

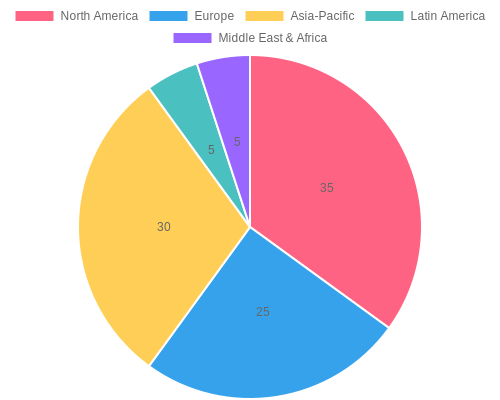

User Adoption Statistics of X-ray Inspection Technology

X-ray inspection technology has seen significant adoption across various jurisdictions and industries, particularly in transportation, logistics, and security. Here are some noteworthy statistics that provide context on its effectiveness and acceptance:

- North America:

- Accounts for 25% of the global X-ray inspection market.

- Over 80% of ports and border crossings are equipped with high-resolution scanning technology.

- The implementation of AI-powered cargo screening has increased by 50%, enhancing the security measures at customs checkpoints.

- Europe:

- Holds 20% of the market.

- More than 75% of seaports utilize stationary X-ray scanning systems.

- Over 65% of border crossings have adopted AI-based cargo screening to strengthen security measures.

- Asia-Pacific:

- Dominating the market with 50% of global demand, spurred by rising trade activities.

- Over 80% of major seaports have deployed high-energy X-ray scanners, with China contributing to 40% of total installations.

- Middle East & Africa:

- Experiencing a 30% rise in X-ray inspection demand due to increasing trade.

- More than 60% of seaports in Gulf Cooperation Council countries utilize high-resolution X-ray scanning systems.

- Manufacturing Sector:

- In 2023, accounted for 29.6% of the X-ray Inspection System Market, prominently using X-ray systems for quality control, defect detection, and process control applications.

- Automotive Industry:

- Expected to experience the highest compound annual growth rate (CAGR) from 2024 to 2032, due to the increased adoption of electric vehicles necessitating precise component inspection.

- Airport Cargo Inspection:

- Recognized as the fastest-growing market segment, with a market size of approximately USD 880 million in 2024 and a projected CAGR of 8.3% through 2033, driven by the expansion of air freight and e-commerce sectors.

These adoption statistics illustrate the critical role that X-ray inspection technology plays in enhancing security and operational efficiency in various sectors globally, particularly as the need for effective inspection methods continues to grow.

Graph displaying the global market share of X-ray inspection technology by region and industry sector

Conclusion

The rollout of X-ray inspection technology in Ontario marks a pivotal advancement in commercial vehicle inspections, enhancing efficiency in identifying illegal shipments and bolstering public safety. This technology significantly improves the Ontario Transportation Ministry’s operational processes through high detection rates and rapid, non-invasive inspections. By effectively addressing concerns such as undocumented cargo, X-ray technology is crucial for regulatory compliance and the integrity of Ontario’s transportation systems.

Stakeholders, including the Ontario Trucking Association, are committed to navigating this transition to ensure that the benefits of these technological improvements translate into safer roads and communities. As articulated by Wayne Cooney, the dedication to enhancing road safety through effective measures serves as a cornerstone for this initiative.

Overview of the Implementation Timeline for X-ray Inspection Technology in Ontario

The deployment of X-ray inspection technology in Ontario is structured into several key phases aimed at ensuring a smooth transition to this advanced inspection method. The expected timeline for the rollout can be summarized as follows:

-

Introduction Phase:

This phase involves the announcement and initial discussions regarding the deployment of the technology. During this time, stakeholders such as the Ontario Trucking Association (OTA) will be engaged to gather input and outline the goals of implementation.

-

Pilot Testing:

Shortly after the introduction phase, a pilot program will be initiated. This will involve the use of X-ray technology in select regions to gather data and assess its effectiveness in real-world conditions. Feedback from this phase will be vital for refining protocols and addressing any operational challenges.

-

Training for Inspectors:

Concurrently with pilot testing, training sessions will be organized for MTO officers and inspectors. Ensuring that personnel are proficient in using the X-ray systems is essential for maximizing their effectiveness and ensuring compliance with safety standards.

-

Full Implementation:

Following the successful completion of pilot testing and training, full-scale implementation will commence. This phase will see the integration of X-ray inspection technology across various inspection sites throughout Ontario, promoting enhanced efficiency and safety measures.

-

Ongoing Evaluation:

Post-implementation, there will be continuous monitoring and evaluation of the X-ray systems’ performance. This will involve collecting data on inspection outcomes, efficiency improvements, and any necessary adjustments to enhance the overall effectiveness of the technology in identifying undocumented cargo and illegal shipments.

By carefully sequenced implementation phases, Ontario aims to ensure that the rollout of X-ray inspection technology not only meets operational goals but also maintains a strong focus on public safety and compliance in the commercial vehicle sector.

Additional Resources

For those looking to further understand the regulatory framework surrounding commercial vehicle inspections and the recent advancements in safety measures, the following resources may be helpful:

- Ontario Ministry of Transportation (MTO): Comprehensive details about commercial vehicle safety requirements can be found on the MTO official website.

- Ontario Trucking Association (OTA): For insights on the industry’s current priorities including technology advancements in inspections, check the OTA’s discussions regarding inspection technologies and impacts on trucking here.