In a move reflecting its commitment to innovation in the logistics and transportation sector, Stoughton Trailers has unveiled its latest product: the new Stoughton intermodal container and smart chassis. Designed to not only meet but exceed the demanding needs of modern freight operations, this cutting-edge 53-foot intermodal container offers a remarkable increase of 6.5% in capacity, translating to an additional 262 cubic feet over traditional models. Constructed to endure harsh operating environments, this container embodies Stoughton’s dedication to quality and durability.

Paired with the industry’s first smart chassis, developed in collaboration with Clarience Technologies, the new launch stands as a testament to Stoughton’s ability to harness advanced technologies for enhanced safety and operational efficiency. This article will delve into the innovative features and goals of the Stoughton intermodal container and smart chassis, setting a higher standard in the market and paving the way for future advancements in intermodal transportation.

Product Specifications

The new Stoughton intermodal container is a big change in freight transport with new features that meet the changing needs of the industry. Here are the key features:

Dimensions

- Length: 53 feet

- Internal Width: 100.375 inches

Capacity Increase

One of the best features of this intermodal container is its larger capacity. Compared to regular containers, it offers 6.5% more volume, giving 262 cubic feet more space. This means better loading options, making freight transport more efficient and cost-effective.

Construction Materials

Stoughton Trailers uses strong materials to ensure the container lasts a long time. The containers are made from heavy-duty hot-dip galvanized steel. This type of steel is excellent at resisting rust and wear, which is necessary for handling tough working conditions.

Manufacturing

All Stoughton intermodal containers are proudly made in Wisconsin. This focus on local manufacturing supports the economy and allows for strict quality control throughout the production process.

Overall, the new Stoughton intermodal container is created for those who value durability, increased capacity, and reliability in their logistics operations.

By following these specifications, Stoughton continues to set a higher standard in the intermodal transportation market, offering solutions that help improve operational efficiency and enhance profitability for carriers and freight companies.

Comparison of Traditional Intermodal Containers and Stoughton’s New Design

| Feature | Traditional Intermodal Container | Stoughton’s New Intermodal Container |

|---|---|---|

| Length | 53 feet | 53 feet |

| Internal Width | 100 inches | 100.375 inches |

| Volume | Varies (typically lower) | 6.5% more volume than traditional |

| Material Construction | Varies (often weaker materials) | Heavy-duty hot-dip galvanized steel |

| Manufacturing Location | Various locations | Wisconsin |

| Enhanced Durability | Standard durability | Built for harsh environments |

This table highlights the key differences between traditional intermodal containers and the innovative design introduced by Stoughton Trailers, emphasizing improvements in capacity, durability, and construction materials.

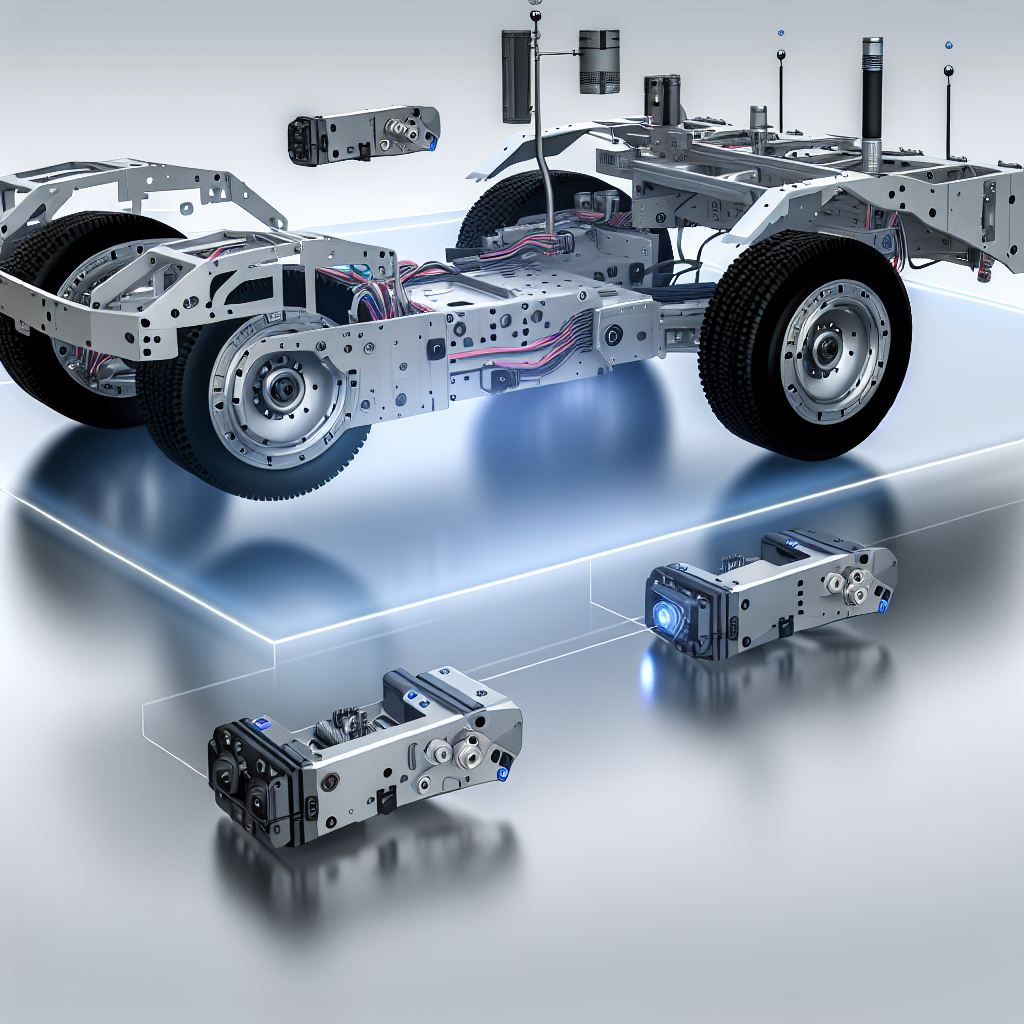

Insights on the Smart Chassis

In a significant advancement for the logistics and transportation industry, Stoughton Trailers has collaborated with Clarience Technologies to launch a state-of-the-art smart chassis. This innovative chassis integrates advanced sensor technology, enhancing operational efficiency, safety, and connectivity within freight transportation.

Auto Connect System

One of the standout features of the smart chassis is the Auto Connect System developed by Electrans Technologies. This system automates the coupling process of the truck and chassis air, electrical, and communication lines in under seven seconds, allowing drivers to remain within the cab. By minimizing the need for physical intervention, it is a critical step toward supporting autonomous vehicle technologies and improving overall safety.

Integrated Safety and Monitoring Features

The smart chassis is equipped with a range of integrated safety and monitoring technologies from Clarience’s subsidiaries:

- Road Ready Monitoring: This feature offers real-time operational visibility through modular control units and includes automatic tire inflation warnings, ABS warning sensors, and container presence sensors, ensuring that operators are immediately informed of any issues that may arise during transportation.

- Rear View Safety (RVS): Enhancing driver awareness, the RVS features wired Ethernet and Air Vue wireless camera systems that provide a 360-degree view around the chassis, significantly reducing blind spots and minimizing the risk of side-swipe incidents.

- Pressure Systems International (P.S.I.): This component helps maintain tire health with an automatic tire inflation system that alerts drivers to tire temperature changes and other critical metrics, ensuring the chassis remains roadworthy and safe during transit.

AI Image Recognition Cameras

Furthermore, the integration of AI image recognition cameras enables precise monitoring of the cargo and trailer conditions. These cameras not only enhance security but also help in maintaining efficient cargo handling processes through real-time analytics and alerts.

Overall, the advanced features and technologies integrated into the smart chassis represent a major leap forward in enhancing safety, efficiency, and operational transparency. As the transportation sector continues to evolve, such innovations are crucial in meeting the rigorous demands of modern logistic frameworks.

In conclusion, the collaboration between Stoughton Trailers and Clarience Technologies brings together expertise and cutting-edge technology, setting a new standard for safety and efficiency in the industry. With the smart chassis ready to hit the roads, operators can expect improved performance and reliability, supported by the latest advancements in transport technology.

Stakeholder Perspectives on Innovation and Customer Impact

The launch of the new Stoughton intermodal container and smart chassis has drawn significant attention from industry leaders, particularly Pat Gunn and Paul Sniegocki, who underscore the importance of innovation and customer value in this venture.

Pat Gunn expressed his commitment to delivering tangible advantages to customers: “At Stoughton, we have always focused on building equipment that delivers a tangible advantage to our customers.” This commitment is reflected in the new container’s enhanced capacity and durability, designed to meet the rigorous demands of modern logistics.

Paul Sniegocki, on the other hand, highlighted the collaborative nature of these innovations, stating, “Innovation doesn’t happen in isolation – it happens through strong partnerships and shared expertise.” This perspective reinforces the collaboration with Clarience Technologies that resulted in the development of the industry’s first smart chassis, equipped with cutting-edge sensor and safety technologies.

Together, these insights from Pat Gunn and Paul Sniegocki illustrate a strong commitment to innovation not just as a goal, but as a shared journey that involves listening to customer needs and partnering effectively to provide superior solutions in the logistics and transportation sector.

The Impact and Advantages of Stoughton’s New Design

The new Stoughton intermodal container and smart chassis hold substantial market implications for logistics companies. With the industry’s growing demand for efficiency and reliability in freight transport, Stoughton’s innovative designs offer a pathway to enhanced operational effectiveness, particularly through increased capacity and superior durability.

Market Implications

Stoughton’s 53-ft intermodal container represents a significant leap forward, boasting a 6.5% increase in volume over standard containers. This expanded capacity allows logistics companies to load more goods per trip, ultimately reducing transportation costs and emissions by maximizing each haul’s potential. The ability to carry an additional 262 cubic feet not only enhances the logistics process but also serves as a catalyst for operational optimization, allowing companies to respond more effectively to varying market demands.

Moreover, the smart chassis, equipped with advanced sensor and safety technologies, elevates operational efficiency. By automating coupling processes and providing real-time monitoring of performance indicators, this chassis supports a safer and smoother operation for drivers, reducing turnaround time at docks and improving overall fleet management. This seamless integration of technology aligns with the logistics industry’s trends towards automation and connectivity, making Stoughton’s innovations particularly appealing.

Potential for Bottom-Line Success

Quotes from industry leaders highlight the financial advantages of these innovations. As one stakeholder noted, “This new intermodal container sets a higher standard in the market – giving carriers the durability they expect with the added capacity that drives real bottom-line success.” This sentiment encapsulates the potential impact on carriers’ profit margins, with increased loads translating directly into greater revenue opportunities.

Furthermore, the collaboration between Stoughton and Clarience Technologies exemplifies how strategic partnerships can lead to innovative solutions that not only meet but exceed customer expectations. “Innovation doesn’t happen in isolation – it happens through strong partnerships and shared expertise,” another leader emphasized, reinforcing the significance of collaboration in driving industry advancements.

In conclusion, Stoughton Trailers’ new intermodal container and smart chassis are set to revolutionize logistics operations. By enhancing capacity, durability, and safety, these innovations present a compelling case for carriers looking to improve their efficiency and financial performance in a competitive market. The tangible benefits offered by this cutting-edge equipment signal a bright future for logistics companies willing to embrace innovation.

In conclusion, the introduction of Stoughton Trailers’ new intermodal container and smart chassis marks a significant milestone in the logistics optimization and transportation industry. Throughout this article, we have explored the innovative features of the 53-foot intermodal container, which offers a remarkable 6.5% increase in capacity, and the groundbreaking smart chassis developed in collaboration with Clarience Technologies. These advancements are not merely enhancements; they represent a commitment to setting higher standards in durability and operational efficiency.

The impact of such innovations is profound. They respond to the pressing demands of modern logistics by optimizing freight operations and enhancing safety through advanced technology integration. Stoughton Trailers is not only driving change with superior products but is also fostering partnerships that empower the industry to evolve. As the logistics landscape continues to shift towards automation and connectivity, Stoughton’s initiatives provide a roadmap for the future, illustrating the essential role of innovation in achieving operational success. By leading the way with their latest designs, Stoughton Trailers is exemplifying how strategic advancements can propel the industry forward into a new era of logistics excellence.

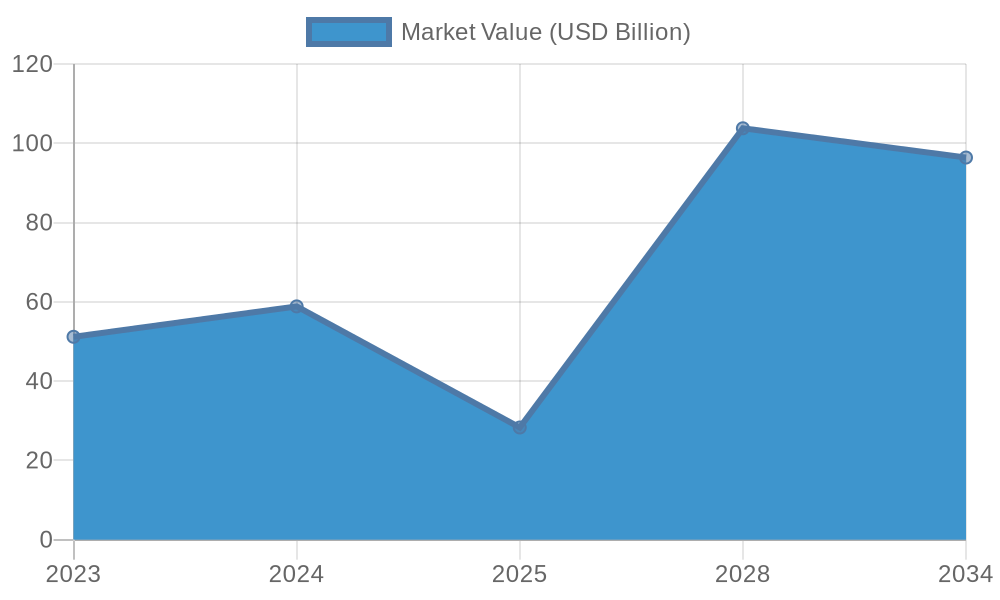

User Adoption Data for Intermodal Containers and Smart Chassis

Recent statistics show a compelling shift in the logistics industry towards intermodal containers and smart chassis, highlighting their growing importance and market presence.

Intermodal Containers:

- The global intermodal freight transportation market was valued at approximately USD 25.38 billion in 2024, with projections estimating it will reach USD 57.43 billion by 2033. This showcases a substantial growth trajectory, reflecting increased efficiency and adaptability in freight operations. (Business Research Insights)

- North America is expected to represent over 35% of the market share in 2025, driven by established rail infrastructure and major intermodal hubs, primarily in cities like Chicago and Los Angeles. This indicates a strong regional preference for intermodal solutions in logistics.

- A notable trend includes the rising adoption of smart logistics technologies, with approximately 40% of logistics providers anticipated to integrate AI and IoT solutions by 2025, demonstrating a shift towards digitalization and optimization in intermodal freight management.

Smart Chassis:

- As of 2023, the smart chassis market is evolving with the brake-by-wire system accounting for 50% of total market share, indicating significant interest in modern safety features in vehicle logistics. (Verified Market Reports)

- Smart chassis applications within passenger vehicles commanded a 70% share in 2023, emphasizing the critical role of advanced safety and autonomous technologies in market dynamics. Such features are driving increased installations in logistics operations.

- The major forces propelling the smart chassis segment are centered around safety and security enhancement needs, advancements in autonomous vehicle technology, and the overall growth of electric vehicle adoption.

Conclusion

The convergence of these statistics reveals that intermodal containers and smart chassis are not only essential for modern logistics operations but are also at the forefront of technological advancements that enhance operational efficiency, safety, and sustainability across the industry. Their increased adoption is set to redefine logistics standards, reflecting a stronger focus on capacity and intelligence in freight transportation.

For more comprehensive insights into containerization trends and their impact on logistics, you can explore Container Technology and its Adoption to stay updated on market movements.

This graph illustrates the growth trends in the intermodal freight transportation market, showing significant increases in market value from 2023 to 2034, corresponding with advancements in technology and user preferences.