Welcome to the exciting world of off-road testing, where military and utility trucks demonstrate their off-road capability against the most challenging terrains. Iconic vehicles such as the 1992 M35A3 Bobbed Deuce and the rugged 1986 Mercedes-Benz Unimog 4×4 confront obstacles ranging from treacherous deep sand to unforgiving rocky paths and classic tank traps.

These encounters not only highlight their engineering prowess but also emphasize unique challenges such as navigating through mud and steep inclines, which can mean the difference between success and failure for both driver and vehicle.

Join us as we delve into the thrilling unpredictability of off-road testing and uncover which formidable truck prevails in a contest of endurance and power. Are you ready to root for your favorite?

Importance of Off-Road Testing for Military and Utility Trucks

Off-road testing is essential for military and utility trucks to ensure their performance, reliability, and user safety across diverse terrains. These vehicles must operate effectively in challenging environments such as deserts, forests, mountains, and urban areas, where standard vehicles would struggle.

Performance and Reliability

Comprehensive off-road testing evaluates a vehicle’s ability to navigate various terrains, ensuring it maintains traction, maneuverability, and stability. This process identifies potential weaknesses, allowing for design refinements before deployment. As noted by TK Engineering Oy, “Thorough testing processes are the cornerstone of reliable off-highway vehicles… comprehensive testing ensures components and systems perform consistently under extreme conditions.” [tke.fi]

Additionally, testing in varied terrains assesses a vehicle’s durability and longevity, focusing on its capacity to withstand prolonged use under demanding conditions. This includes evaluating the stress resistance of structural components and the fatigue life of critical parts. [forcedeploy.com]

User Safety

Ensuring user safety is paramount in off-road testing. Vehicles are subjected to rigorous trials to verify their stability and control in challenging conditions. The Air Force Safety Center emphasizes the importance of tactical vehicle safety, stating, “Reducing tactical vehicle mishaps helps increase DAF readiness for both personnel and equipment.” [safety.af.mil]

Moreover, advanced diagnostics and real-time performance monitoring, integral to modern off-road vehicles, play a crucial role in user safety. These technologies allow for immediate adjustments and proactive maintenance, reducing the risk of accidents and equipment failure. [motorizedcraze.com]

Expert Insights

Experts highlight the necessity of off-road testing in developing autonomous military vehicles. Roger Brereton, head of sales at Pailton Engineering, explains that such testing is crucial due to the complexity and unpredictability of terrains these vehicles must encounter. He notes that military vehicles must perform reliably in unpredictable and often adverse conditions, without the luxury of clear paths or consistent terrains. [pailton.com]

In summary, off-road testing is vital for military and utility trucks to ensure they can perform reliably and safely in diverse and challenging environments. Through rigorous evaluation, potential issues are identified and addressed, leading to vehicles that meet the demanding requirements of their operational contexts.

Detailed Comparison of the 1992 M35A3 and 1986 Mercedes-Benz Unimog

The 1992 M35A3 and the 1986 Mercedes-Benz Unimog are both renowned for their off-road capabilities, yet they differ significantly in design, specifications, and performance across various terrains.

1992 M35A3:

- Engine and Transmission: Equipped with a Caterpillar 3116 diesel engine producing approximately 170 horsepower, paired with an Allison automatic transmission.

- Drive System: Features a 6×6 drivetrain, providing power to all wheels for enhanced traction.

- Suspension and Axles: Utilizes leaf spring suspension with solid axles, offering durability but limited wheel articulation compared to coil spring systems.

- Ground Clearance and Fording Depth: Offers substantial ground clearance suitable for off-road conditions; however, specific measurements are not readily available.

- Off-Road Performance: Designed for military logistics, the M35A3 performs well in various terrains, including mud and rocky environments. Its 6×6 configuration aids in navigating challenging conditions, though its heavier weight may affect maneuverability in soft terrains like sand.

1986 Mercedes-Benz Unimog:

- Engine and Transmission: Typically equipped with a Mercedes-Benz OM352 5.7L inline-six diesel engine, producing around 110 horsepower, coupled with an 8-speed manual transmission.

- Drive System: Features full-time all-wheel drive with portal axles, enhancing ground clearance and off-road capability.

- Suspension and Axles: Employs coil spring suspension with torque tube technology, allowing axle articulation up to 30 degrees, ensuring all wheels maintain contact with the ground over uneven terrain.

- Ground Clearance and Fording Depth: Provides approximately 500 mm (19.7 inches) of ground clearance and can ford water depths up to 1.2 meters (47.2 inches). [source]

- Off-Road Performance: The Unimog’s design excels in extreme off-road conditions, including sand, rocks, and mud. Its portal axles and flexible frame allow it to navigate obstacles like one-meter-high boulders. [source]

Comparison in Off-Road Conditions:

- Sand: The Unimog’s lighter weight and tire pressure control system provide an advantage in sandy terrains, reducing the risk of becoming bogged down.

- Rocks: Both vehicles are capable in rocky environments; however, the Unimog’s superior axle articulation and ground clearance allow it to traverse larger obstacles more effectively.

- Mud: The M35A3’s 6×6 drivetrain offers stability in muddy conditions, but the Unimog’s design, including differential locks and flexible suspension, provides enhanced traction and maneuverability.

In summary, while both the 1992 M35A3 and the 1986 Mercedes-Benz Unimog are competent off-road vehicles, the Unimog’s specialized design features grant it superior performance in extreme off-road conditions.

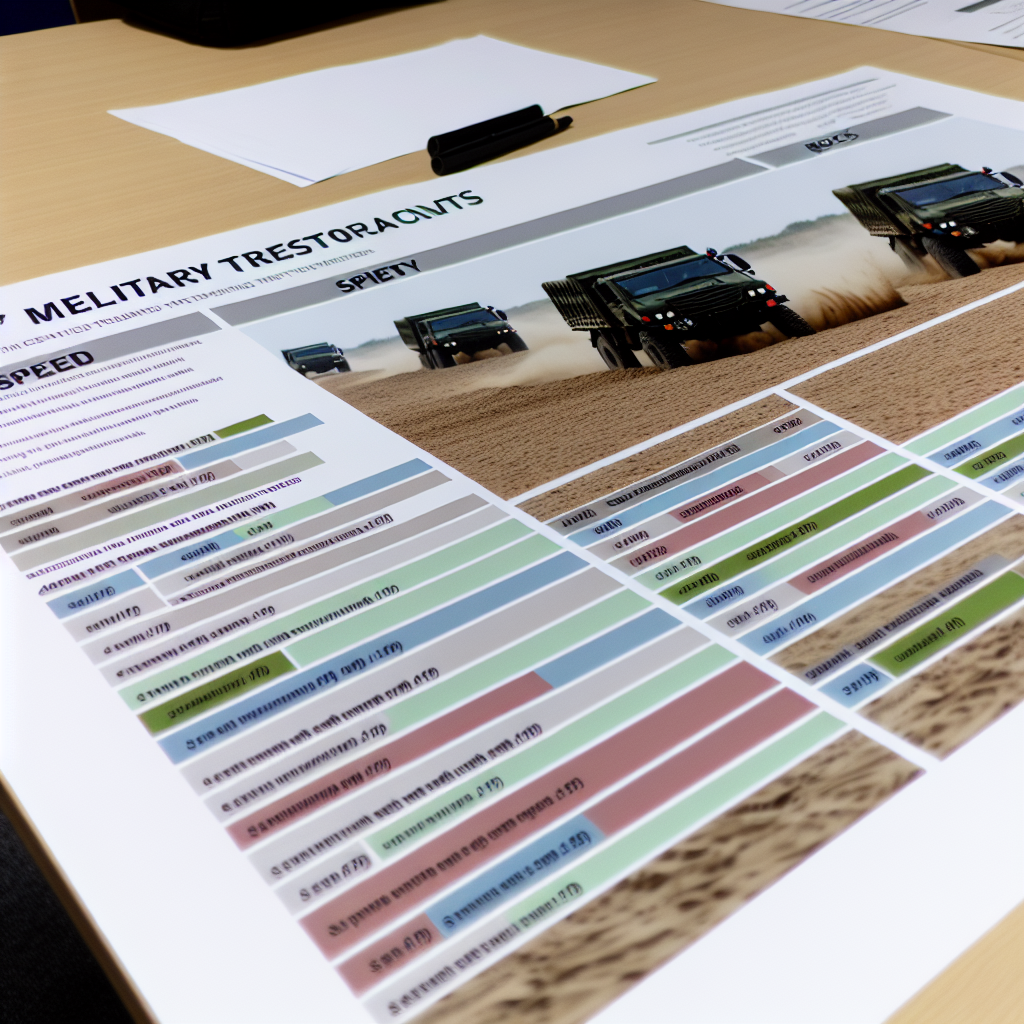

Comparison Table of M35A3 and Unimog Specifications

| Parameter | 1992 M35A3 | 1986 Mercedes-Benz Unimog |

|---|---|---|

| Engine | Caterpillar 3116 diesel engine | Mercedes-Benz OM352 5.7L inline-six diesel engine |

| Horsepower | Approximately 170 hp | Approximately 110 hp |

| Transmission | Allison automatic transmission | 8-speed manual transmission |

| Drive System | 6×6 drivetrain | Full-time all-wheel drive |

| Suspension | Leaf spring suspension | Coil spring suspension with torque tube technology |

| Axles | Solid axles | Portal axles |

| Ground Clearance | Not specified | Approximately 500 mm (19.7 inches) |

| Fording Depth | Not specified | Up to 1.2 meters (47.2 inches) |

| Off-Road Performance | Good, with emphasis on stability | Excellent, adaptable to extreme conditions |

| Weight | Heavier due to 6×6 configuration | Lighter, better maneuverability in sand |

This table showcases the key specifications and features of both vehicles, emphasizing their unique strengths and design characteristics that impact their off-road performance.

User Adoption and Operational Capabilities of Military Trucks

Military trucks are specifically engineered to perform effectively across a multitude of terrains, including deserts, forests, and rocky environments. Their operational capabilities are enhanced through specialized design features and technologies that address the unique challenges presented by each landscape.

Operational Capabilities and Terrain Adaptation

- Desert Environments: Military vehicles operating in deserts are equipped with enhanced cooling systems and dust filtration mechanisms to withstand extreme heat and sandy conditions. Robust suspension systems and specialized tire treads ensure effective mobility over loose, shifting sands. [source]

- Rocky and Mountainous Terrain: Vehicles designed for rocky landscapes feature high-torque engines, reinforced chassis, and articulated suspension systems. These attributes enable them to navigate steep inclines and uneven surfaces, maintaining stability and control in rugged environments. [source]

- Mud and Marshlands: To traverse muddy and marshy terrains, military trucks are equipped with specialized traction control systems, rugged tire configurations, and high ground clearance. Advanced differential lock mechanisms provide stability and prevent vehicles from becoming stuck in soft ground. [source]

User Adoption and Market Insights

- Market Growth: The global military truck market is projected to grow at a compound annual growth rate (CAGR) of 3.02% from 2022 to 2029, reflecting increased demand for versatile and capable military vehicles. [source]

- Regional Contributions: In 2023, North America accounted for approximately 35% of the military off-road vehicles market, followed by Europe at 30%, and Asia Pacific at 20%. The Asia Pacific region is identified as the fastest-growing market, driven by increased defense spending and modernization efforts. [source]

- Vehicle Segmentation: The military truck market is segmented by weight class into light, medium, and heavy categories. Medium weight class trucks dominate nearly 45% of the market, balancing payload capacity and maneuverability, making them suitable for diverse terrains and missions. [source]

Performance Evaluation in Diverse Terrains

- Simulation Studies: Research utilizing multifractal artificial terrain generation has demonstrated that as terrain roughness increases, the success rate of autonomous ground vehicles decreases. Specifically, increasing the fractal dimension from 2.3 to 2.6 resulted in a median success rate decrease of 47.5%, highlighting the challenges posed by more rugged terrains. [source]

- Benchmarking Off-Road Mobility: The development of benchmarks like Verti-Bench provides standardized evaluation of military vehicles’ performance in vertically challenging off-road environments. Such benchmarks assess vehicles across various terrains, including rigid and deformable surfaces, to ensure operational effectiveness. [source]

These insights underscore the importance of continuous adaptation and evaluation of military trucks to meet the demands of diverse operational environments, ensuring their effectiveness and reliability in various terrains.

Real-World Testing Conditions for Military and Utility Trucks

The evaluation of military and utility trucks involves rigorous testing under a variety of challenging conditions that play a crucial role in determining their performance capabilities. The testing takes place in environments that replicate the extreme scenarios these vehicles may encounter during actual operational missions.

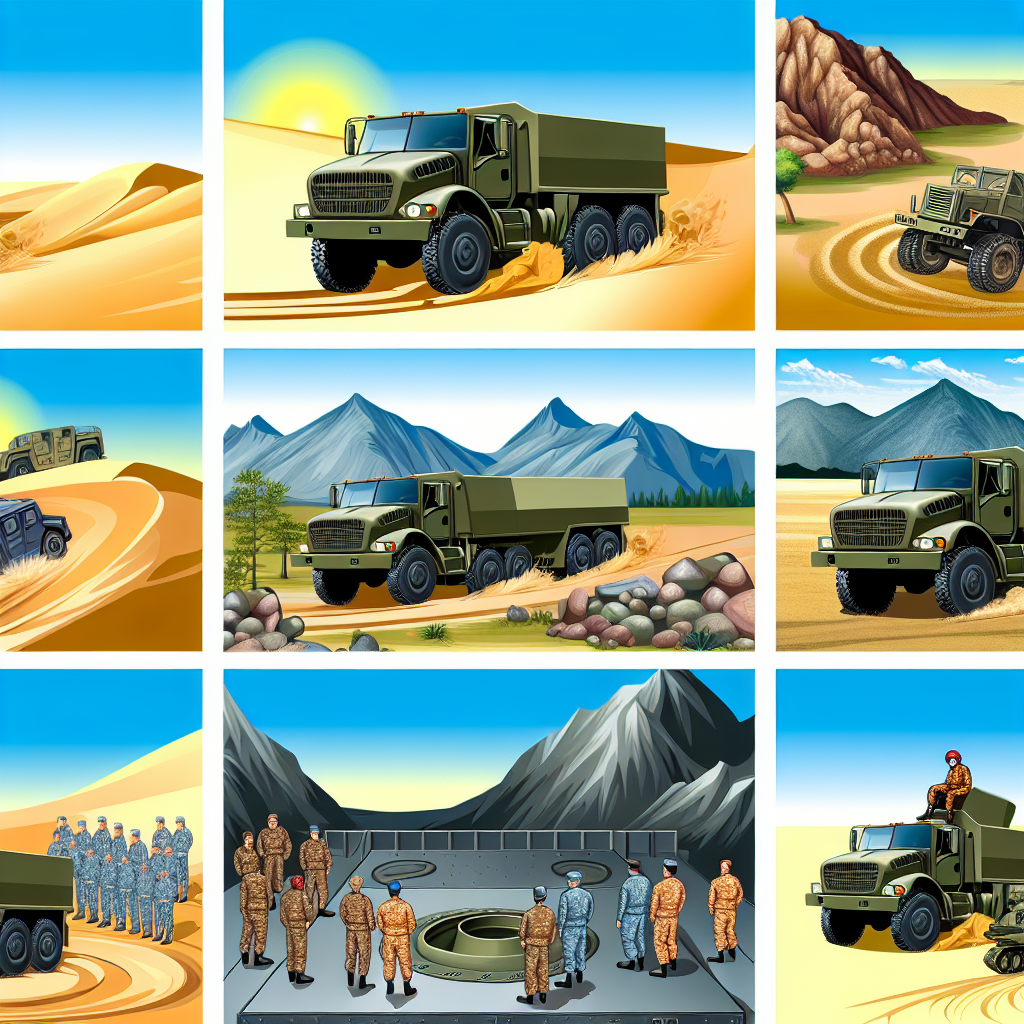

Sand Terrain

One of the primary testing conditions includes deep sandy environments, which pose a significant challenge for any vehicle. The loose nature of this terrain requires trucks to exert more power to maintain movement, impacting their fuel efficiency and steering response. Vehicles are assessed based on their ability to navigate through shifting sands without becoming bogged down. Tire design and pressure management play critical roles in this setting, affecting traction and overall maneuverability.

Rocky Terrains

Navigating rocky paths is another essential aspect of off-road testing. This terrain tests a vehicle’s suspension system and ground clearance. Trucks are evaluated on how well they can handle uneven surfaces, including boulders and sharp rocks. The ability to articulate the axles effectively while maintaining tire contact with the ground is key for preventing damage to both the vehicle and the terrain. Engineers observe how vehicles absorb impacts from rugged surfaces and how well they maintain control over varying elevations and slopes.

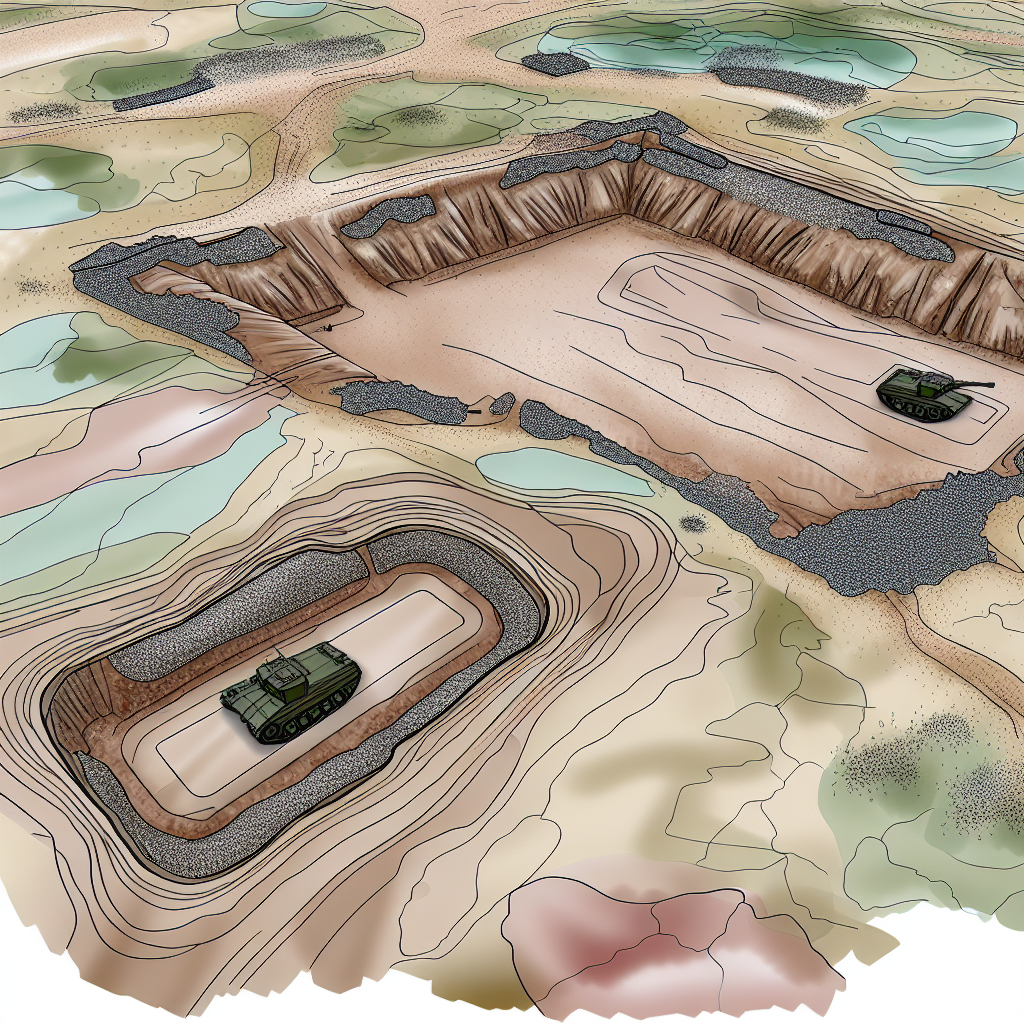

Tank Traps

Tank traps are specifically designed obstacles used in testing to evaluate a truck’s capability to traverse deep mud and water-filled ditches. These conditions simulate battlefield scenarios where vehicles might encounter obstacles designed to impede movement. Successful navigation through tank traps demonstrates a vehicle’s all-terrain capability and showcases its design advantages, such as differential locks and power distribution systems that enhance performance in adverse conditions.

Other Relevant Factors

Additional factors impacting performance evaluations include the vehicle’s weight, engine power, and construction materials. Heavier vehicles may struggle in sandy or marshy areas, while lightweight designs might excel but face stability challenges in rough terrains. Furthermore, the evaluation also considers weather conditions—testing in both dry and wet environments helps delineate the performance thresholds and limitations of each vehicle.

In summary, the testing conditions for military and utility trucks are multifaceted, involving an array of terrains that simulate real-world challenges. The insights gained from this rigorous evaluation process are vital for enhancing vehicle design and operational readiness, ensuring that they can withstand the most demanding environments encountered in the field.

Testing Outcomes Table

This table illustrates comparative performance metrics across different testing conditions, providing visual clarity to the evaluation process of military trucks.

Conclusion

In the rigorous off-road testing of the 1992 M35A3 Bobbed Deuce and the 1986 Mercedes-Benz Unimog, several compelling insights emerged. Overall, the Unimog outperformed the M35A3 when it came to navigating extreme terrains such as sandy, rocky, and muddy conditions. Its lighter weight, independent suspension system, and superior axle articulation contributed to enhanced mobility and traction, enabling the Unimog to adeptly handle challenging obstacles that the M35A3 struggled with. For instance, while the M35A3 showcased stability in muddy situations due to its 6×6 drivetrain, it was ultimately the Unimog’s flexible frame and tire design that allowed for better performance across various scenarios.

Perhaps the most surprising finding was the M35A3’s difficulty in traversing soft sand, primarily due to its weight, which occasionally hindered its maneuverability and caused it to become stuck. This implication for potential users underscores the need for careful vehicle selection based on anticipated operating conditions; a lightweight and agile vehicle like the Unimog may be preferable for operations in sandy or uneven environments where agility is paramount.

In conclusion, while both vehicles are designed for rigorous conditions, the Unimog emerges as the more versatile option for off-road enthusiasts and military applications requiring adaptability across diverse terrains. This versatility is crucial for effective military logistics and terrain adaptability, ensuring that users are equipped for success in varied environments. Users should consider these insights when evaluating their vehicle needs, especially regarding operational demands in challenging landscapes.

Expert and User Quotes on Military Trucks Performance

- Jay Couch on Off-Road Performance: “The adaptability of military trucks in challenging terrains like sand and mud often showcases the essential balance of power and engineering. They need to provide both reliability and performance under unpredictable conditions.”

- User Insight on Humvee Durability: “From my experience in the field, the Humvee’s ability to perform reliably in rocky environments is remarkable. It takes a beating but keeps going, which is what you want from your military vehicle.”

- Comment on the Mercedes-Benz Unimog: “The Unimog is not just durable; it’s incredibly versatile. Whether it’s delivering troops or serving as a mobile workshop, its off-road capabilities truly shine, making it indispensable in combat zones.”

- Pinzgauer User Feedback: “The Pinzgauer performs exceptionally well in harsh environments. Its design prioritizes mobility and traction, allowing it to navigate through rough terrains where other vehicles falter.”

- Oshkosh M-ATV Evaluation: “The M-ATV stands out with its TAK-4 suspension system. It provides incredible off-road mobility while ensuring the safety of our troops, something that we value deeply in our operations.”

- Commentary on the KamAZ-4350: “We took the KamAZ-4350 through deep water, and it handled beautifully. Its off-road capabilities are well-suited for heavy-duty military transport.”

- Shaanxi HMV3 Performance Overview: “The HMV3’s cross-country performance and armored cab make it a reliable choice for logistics operations, navigating through both combat zones and rough landscapes.”

- Tatra 816 Expertise: “The Tatra 816’s independent suspension and strong backbone frame give it incredible stability and maneuverability when traversing deep mud and uneven ground.”

- M809 Series Practical Experience: “The M809 series is built for tough conditions. It can effectively maintain traction and stability across various terrains, which is crucial for any military logistics operation.”

- User Perspective on the Kaiser Jeep M715: “Even after decades, the M715 still impresses in rough terrains. Its blend of military sturdiness with civilian components makes it a unique asset in any fleet.”

These quotes provide valuable insight into the performance and reliability of military trucks in off-road scenarios, highlighting the perspectives of both experts and end-users.

Transition to Detailed Comparison

As we transition from discussing the overall importance of off-road testing, it is crucial to consider how these tests translate into the specific features of vehicles such as the 1992 M35A3 and the 1986 Mercedes-Benz Unimog. Each of these trucks embodies unique engineering solutions designed to tackle the very challenges that rigorous testing entails. From the robust drive systems to the advanced suspensions, understanding these characteristics will shed light on why accurate testing is so pivotal for military and utility trucks.

Let us delve into a detailed comparison of these two formidable vehicles and how their specific features contribute to their performance in extreme conditions.

Comparison Table of M35A3 and Unimog Specifications

| Parameter | 1992 M35A3 | 1986 Mercedes-Benz Unimog |

|---|---|---|

| Engine | Caterpillar 3116 diesel engine | Mercedes-Benz OM352 5.7L inline-six diesel engine |

| Horsepower | Approximately 170 hp | Approximately 110 hp |

| Transmission | Allison automatic transmission | 8-speed manual transmission |

| Drive System | 6×6 drivetrain | Full-time all-wheel drive |

| Suspension | Leaf spring suspension | Coil spring suspension with torque tube technology |

| Axles | Solid axles | Portal axles |

| Ground Clearance | Not specified | Approximately 500 mm (19.7 inches) |

| Fording Depth | Not specified | Up to 1.2 meters (47.2 inches) |

| Off-Road Performance | Good, with emphasis on stability | Excellent, adaptable to extreme conditions |

| Weight | Heavier due to 6×6 configuration | Lighter, better maneuverability in sand |

This table showcases the key specifications and features of both vehicles, emphasizing their unique strengths that impact off-road performance.